Our products

Home » Special pipes » egeSlurry® with protective interior

egeSlurry® with protective interior

For the transportation of abrasive slurry type media. Dim ø 160–630 mm.

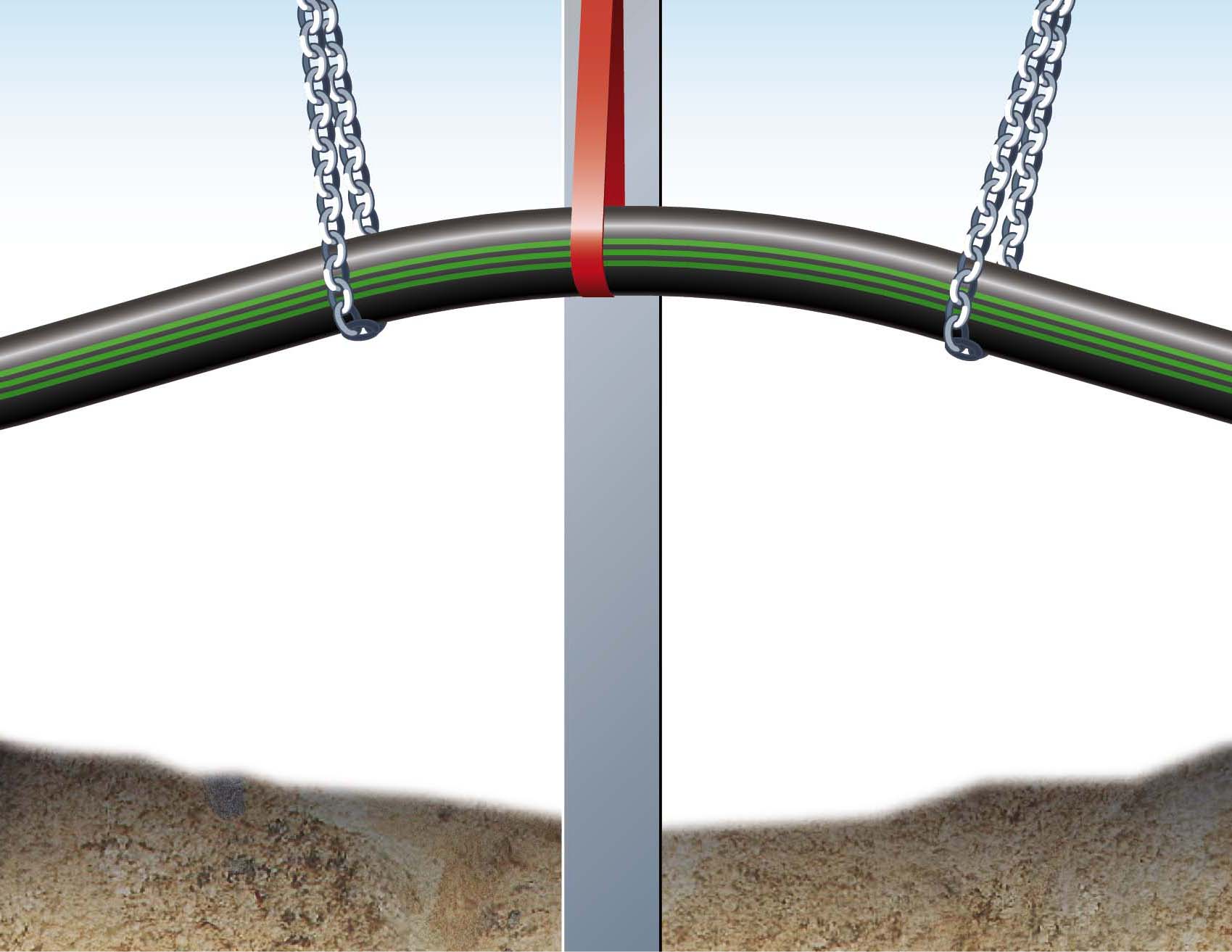

Some specific industries require the transportation of coarse and abrasive media, for example in the mining industry, and the transportation of slurry, which consists of tailings and mine water. Due to the abrasive characteristics of these media, special requirements are placed on the pipe systems that are used. This type of pipe system is used not only in the mining industry, but also in maritime land recovery (transportation of sand water mixture), the transportation of granules and pellets and animal feed. For these applications, Extena offers the durable egeSlurry® system.

egeSlurry®

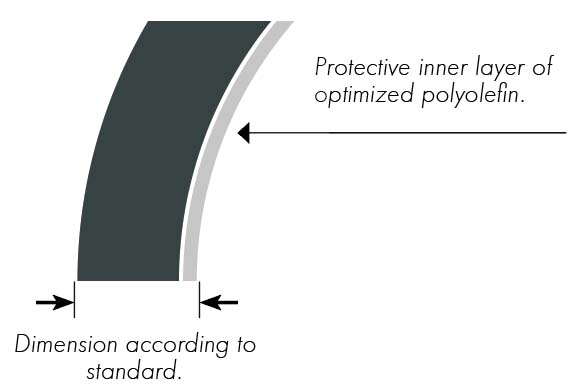

egeSlurry® is a pressure pipe system designed specifically for the hydraulic and pneumatic transportation of abrasive media. These pipes and pipe fittings have high wear resistance for maximum service life and provide efficient transportation thanks to their multilayer design with a patented internal polyolefin coating.

Homogeneous pipes

Multilayer pipes can have strippable or homogeneous layers. The strippable layers can be stripped from the main pipe while homogeneous layers are an integral part of the pipe. egeSlurry® is a homogeneous pipe with an integrated reinforcement layer on the inside.

egeSlurry®

egeSlurry® is a pressure pipe system designed specifically for the hydraulic and pneumatic transportation of abrasive media. These pipes and pipe fittings have high wear resistance for maximum service life and provide efficient transportation thanks to their multilayer design with a patented internal polyolefin coating.

Homogeneous pipes

Multilayer pipes can have strippable or homogeneous layers. The strippable layers can be stripped from the main pipe while homogeneous layers are an integral part of the pipe. egeSlurry® is a homogeneous pipe with an integrated reinforcement layer on the inside.

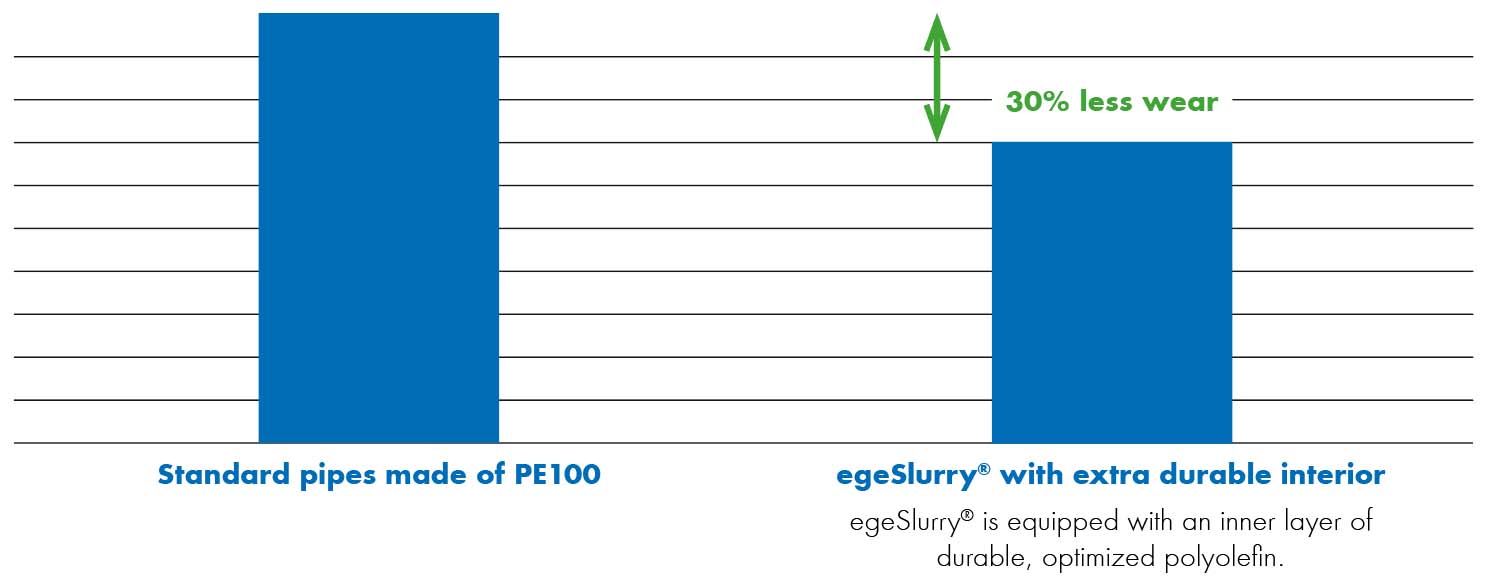

egeSlurry® has significantly reduced wear (30%) compared to traditional PE 100 interiors according to ISO 15527 sand/slurry test.

Produktfördelar

- Increased durability and service life thanks to integrated wear protection

- Longer maintenance intervals, reduced costs and prevention of downtimes

- Installation with established jointing methods, such as welding or the use of flange connections

- Fully integrated system with moulded parts, which are also protected against wear

- Pre-fabricated pipe system solution that facilitates jointing and installation

- Significantly reduced wear on egeSlurry® compared to traditional PE pipes (results from ISO 15527 sand/slurry test)

Pipelaying methods

Traditional pipelaying in trenches.

Suitable for pipelaying adapted for pipes made of PE100 RC.

Suitable for alternative installations.

Suitable for alternative installations.

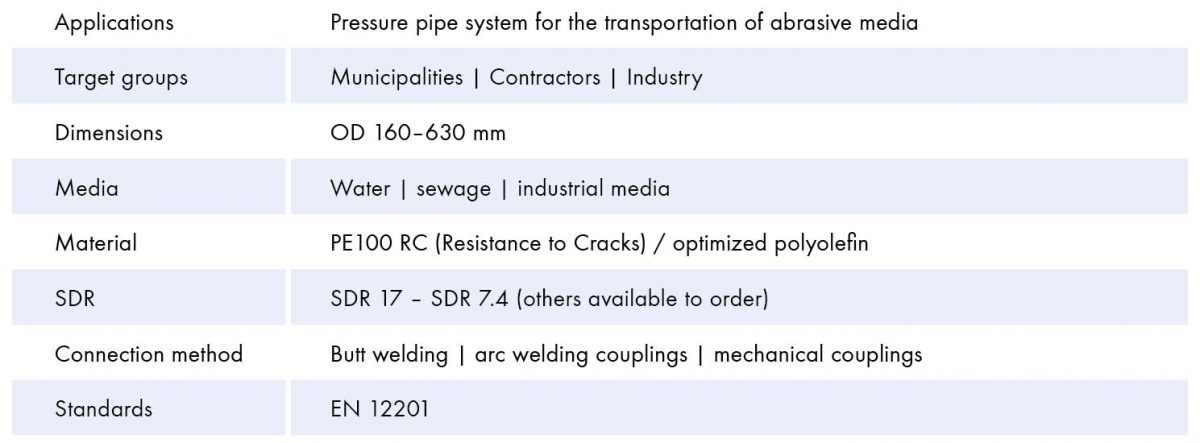

Facts

Pipe fittings

PE pipe fittings

– Injection moulded

– Seamless

– Machined

– Segment welded

Arc welding parts

Complete range of arc welding parts for different applications.

Flange joints

Wide range of flange joints such as loose flanges, SF flanges and HP flanges.

Customized pipe fittings

For egeSlurry® pipes, you can also order customized pipe fittings according to drawing.

Delivery options

Coil

Straight lengths

6, 12, 18, 20 or 22 m

- All pipes are fitted with end caps

- Non-standard lengths can be ordered on request