Our products

Home » Multilayer pipes » SLM® – With sheath

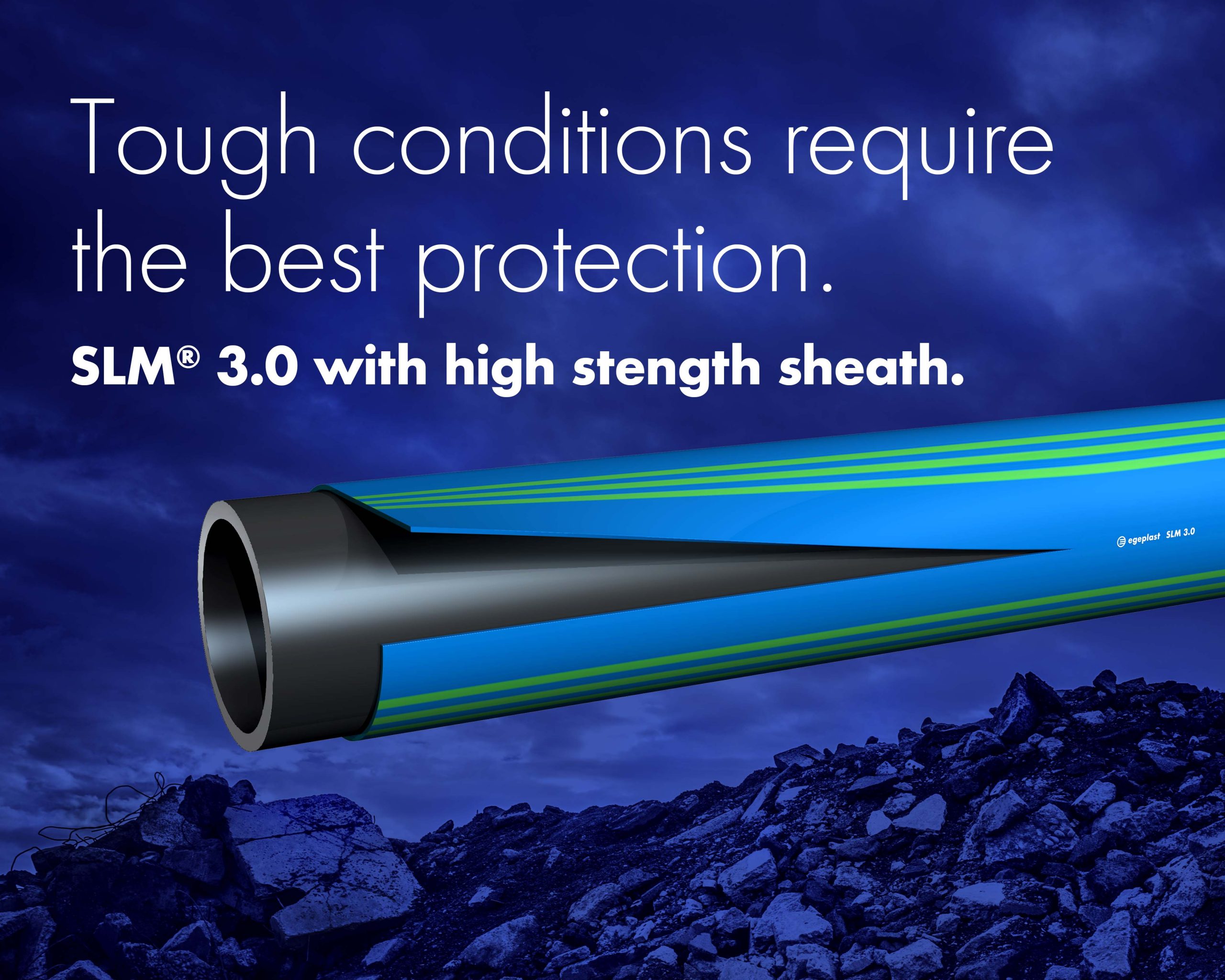

SLM® 3.0 with a high strength PEplus sheath

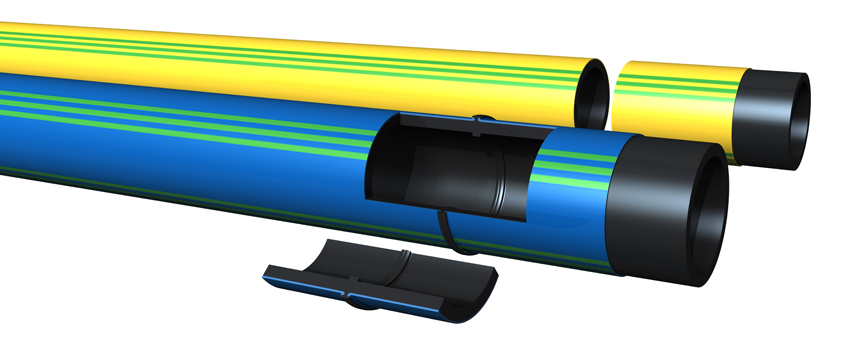

Pipe made of PE100 RC with a protective PEplus sheath.

For water, sewage and gas. Dim ø 25-1200 mm

SLM® 3.0

Standard pipe made of PE100 RC fitted with a protective PEplus sheath.

SLM® 3.0 is easier to use, easier to weld and is a safe and more reliable pipe system. SLM® 3.0 is a standard pipe made of PE100 RC fitted with a high strength sheath (coat) on the outside of the pipe, providing extra protection against scratches and damage that may occur during pipelaying.

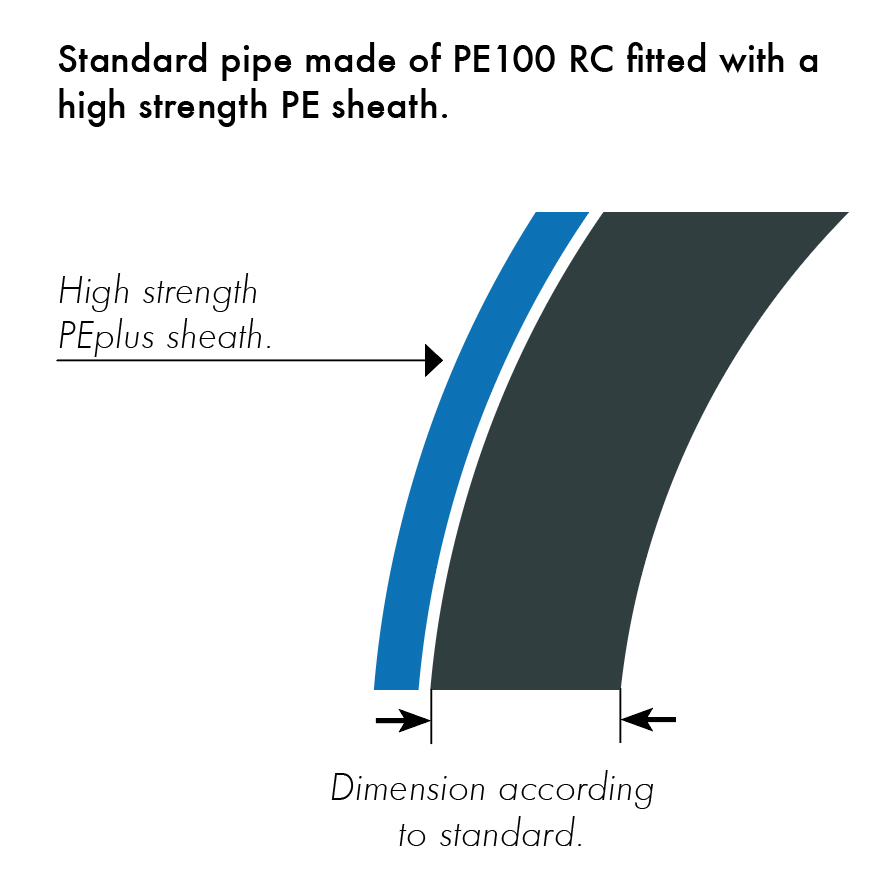

The pipe’s high strength sheath is made of PEplus, with a thickness, in the case of dim 250 mm/SDR17, corresponding to 25% of the pipe’s wall thickness.

Since the sheath is made of polyethylene, it does not need to be removed during butt welding (SLM® 3.0) but can be integrated into the joint, reducing the risk of the sheath being ripped off when performing alternative installation methods such as directional drilling and pipe splitting or when extraction hoods are used.

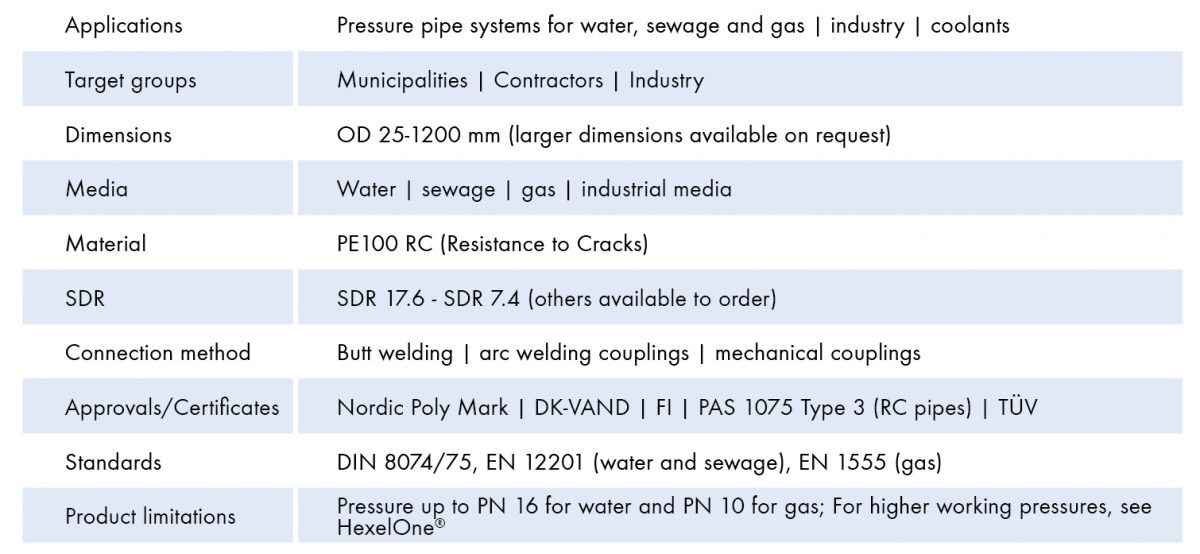

SLM® 3.0 meets the requirements of PAS 1075 Type 3.

Standard pipe made of PE100 RC fitted with a protective PEplus sheath.

SLM® 3.0 is easier to use, easier to weld and is a safe and more reliable pipe system. SLM® 3.0 is a standard pipe made of PE100 RC fitted with a high strength sheath (coat) on the outside of the pipe, providing extra protection against scratches and damage that may occur during pipelaying.

The pipe’s high strength sheath is made of PEplus, with a thickness, in the case of dim 250 mm/SDR17, corresponding to 25% of the pipe’s wall thickness.

Since the sheath is made of polyethylene, it does not need to be removed during butt welding (SLM® 3.0) but can be integrated into the joint, reducing the risk of the sheath being ripped off when performing alternative installation methods such as directional drilling and pipe splitting or when extraction hoods are used.

SLM® 3.0 meets the requirements of PAS 1075 Type 3.

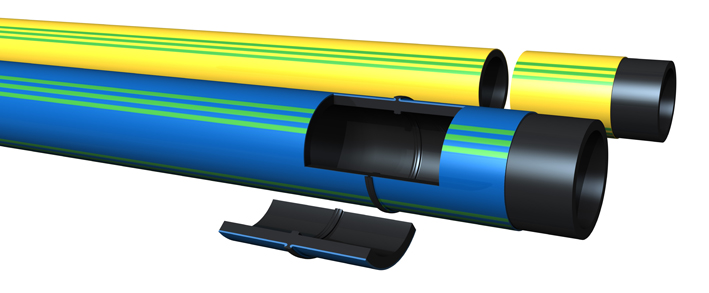

The sheath is welded in the bead – it cannot be ripped off

Since SLM® 3.0 and its sheath are manufactured from the same basic material, i.e. polyethylene, the sheath can be butt welded in the bead. The different layers are then joined together in the weld bead (the sheath merges with the main material), which prevents the sheath from being ripped off during directional drilling or horizontal drawing, etc. when an extraction hood is used. In the case of SLM® DCT, this pipe must be stripped when welding, as it has additional layers of other material.

Since SLM® 3.0 and its sheath are manufactured from the same basic material, i.e. polyethylene, the sheath can be butt welded in the bead. The different layers are then joined together in the weld bead (the sheath merges with the main material), which prevents the sheath from being ripped off during directional drilling or horizontal drawing, etc. when an extraction hood is used. In the case of SLM® DCT, this pipe must be stripped when welding, as it has additional layers of other material.

Product benefits

- Pipe system made of PE100 RC for a safer service life and more efficient pipelaying.

- High strength PEplus sheath corresponding to e.g. 25% of the pipe’s wall thickness at dimension 250 mm/SDR17.

- 60% less wear on a PEplus sheath compared to a PP sheath.

- Butt welding according to DVS standard without having to remove the sheath.

- A pipe system suitable for alternative installation methods where extra pipe protection is required.

- Minimal ovality for safe jointing.

- Complete range of pipe fittings.

Pipelaying method

Traditional pipelaying in trenches.

Suitable for pipelaying adapted for pipes made of PE100 RC.

Also suitable for alternative installation methods.

Approvals

Facts

Pipe fittings

PE pipe fittings

– Injection moulded

– Seamless

– Machined

– Segment welded

Arc welding parts

Complete range of arc welding parts for different purposes.

Flange joints

Wide range of flange joints such as loose flanges, SF flanges and HP flanges.

Customized pipe fittings

For SLM® 3.0, you can also order customized pipe fittings according to drawing.

Delivery options

Coil

Drum

Straight lengths

6, 12, 18, eller 20 m

- All pipes are fitted with end caps

- Non-standard lengths can be ordered on request