Our products

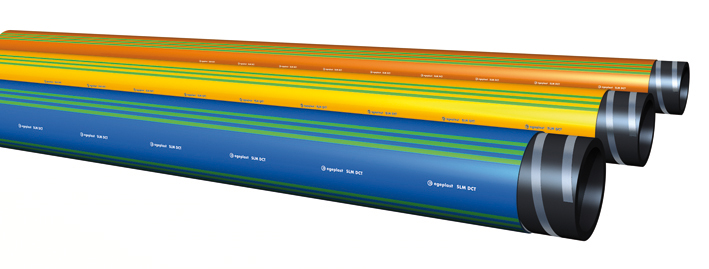

Home » Multilayer pipes » SLM® DCS – with continuous monitoring

NEW!

Extena launches Pressure Pipe SLM® DCS – with continuous monitoring and a high strength protective sheath

Damage to water pipes is a problem for most pipeline owners and involves high repair costs. This type of damage also poses problems for individuals or companies who may lose their access to clean water. And there are additional costs caused by the loss of drinking water, which can increase significantly over time.

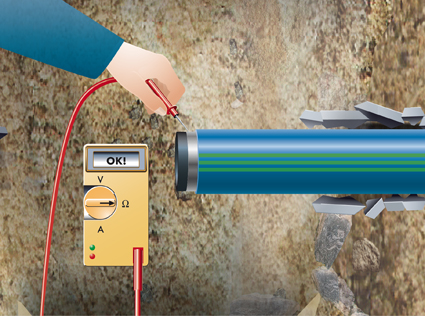

In order to quickly locate damage to a critical pipeline at an early stage and thereby minimise troubleshooting time, Extena is now launching Pressure Pipe SLM® DCS. This pipe gives you full control and automatically alerts you to any damage to a pipeline, with up to one metre accuracy. You can choose between continuous online damage control or performing a control at predetermined intervals.

PE 100 RC, conductive strips and a high strength sheath

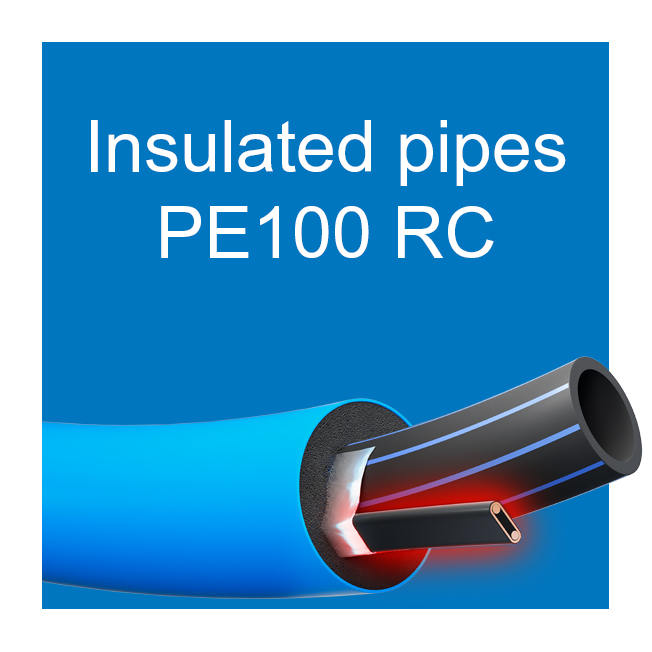

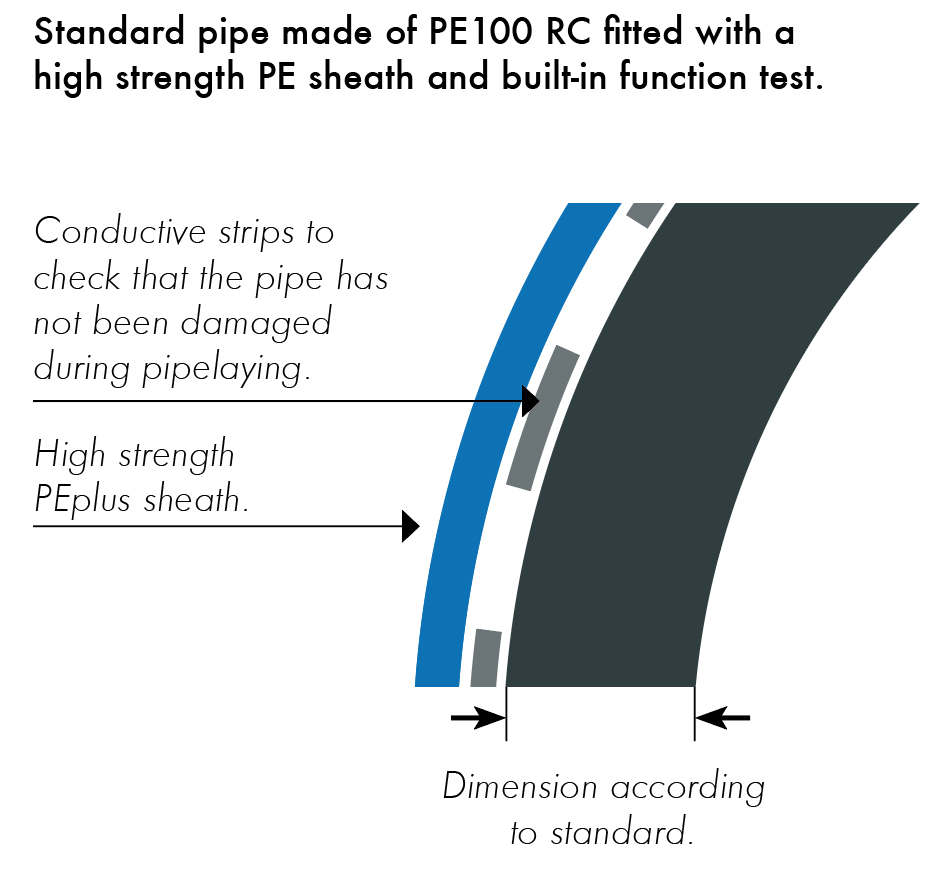

Pressure Pipe SLM® DCS from Extena consists of a standard pipe made of PE100 RC equipped with conductive strips for the rapid detection of possible leaks. The pipe also has a high strength sheath for extra protection. This sheath has a thickness of 1–5 mm depending on pipe dimension. Compared to traditional PE material, the raw material PE 100 RC has about 17 times higher requirements for slow crack growth.

A monitoring device connected to the pipe issues an alarm even in the event of very minor pipe damage. The messages are then sent directly to the control centre or a mobile phone. The system can automatically shut down and reconnect any connected pump systems, thereby preventing water loss at an early stage.

Features

In order to quickly locate damage to a critical pipeline at an early stage and thereby minimise troubleshooting time, Extena is now launching Pressure Pipe SLM® DCS. This pipe gives you full control and automatically alerts you to any damage to a pipeline, with up to one metre accuracy. You can choose between continuous online damage control or performing a control at predetermined intervals.

PE 100 RC, conductive strips and a high strength sheath

Pressure Pipe SLM® DCS from Extena consists of a standard pipe made of PE100 RC equipped with conductive strips for the rapid detection of possible leaks. The pipe also has a high strength sheath for extra protection. This sheath has a thickness of 1–5 mm depending on pipe dimension. Compared to traditional PE material, the raw material PE 100 RC has about 17 times higher requirements for slow crack growth.

A monitoring device connected to the pipe issues an alarm even in the event of very minor pipe damage. The messages are then sent directly to the control centre or a mobile phone. The system can automatically shut down and reconnect any connected pump systems, thereby preventing water loss at an early stage.

Features

- Permanent or on-demand monitoring of a pipe system

- Increased pipeline safety thanks to continuous status updates

- Avoid water loss including consequential damage

- Automated operations such as shutting off a stretch of pipeline

- Fast detection and location of damage with 1 metre accuracy

- Extra protection provided by a high strength 1–5 mm sheath

- Check that no damage has occurred during installation

Product benefits

- Pipe system made of PE100 RC for a safer service life and more efficient pipelaying.

- Built-in function check via conductive aluminium strips between the pipe itself and the outer sheath allows external pipe damage caused during pipelaying to be detected and localized.

- High strength PEplus sheath corresponding to e.g. 25% of the pipe’s wall thickness at dimension 250 mm/SDR17.

- A pipe system suitable for alternative installation methods where extra pipe protection is required.

- Minimal ovality for safe jointing.

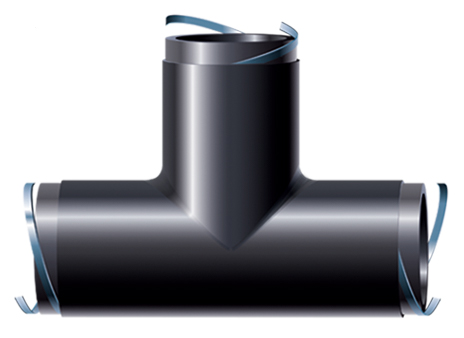

- Complete range of pipe fittings.

Pipelaying method

Traditional pipelaying in trenches.

Suitable for pipelaying adapted for pipes made of PE100 RC.

Also suitable for alternative installation methods.

Built-in function test.

Permanent function check that reports possible damage.

Approvals

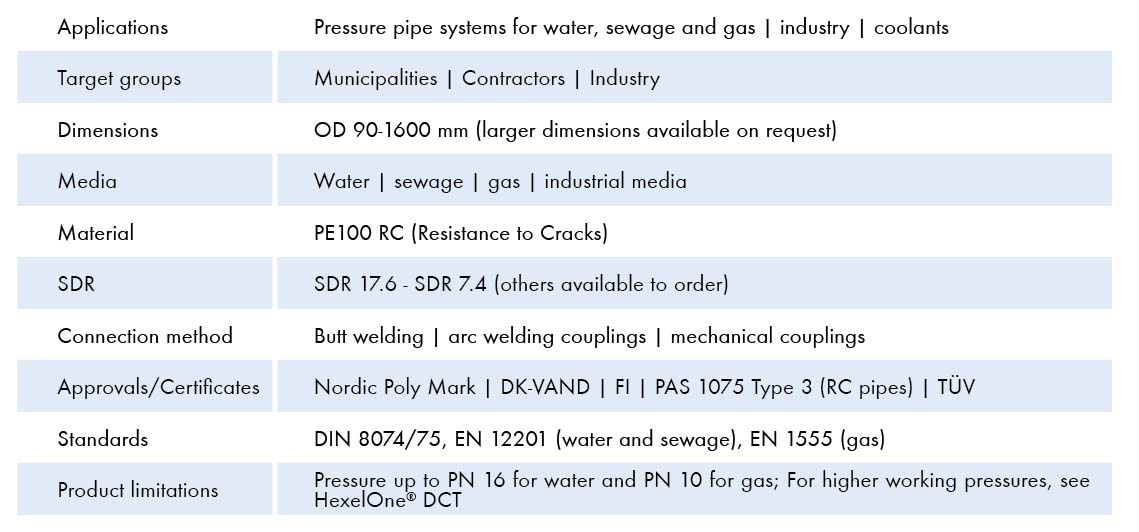

Facts

Pipe fittings

PE pipe fittings

– Injection moulded

– Seamless

– Machined

– Segment welded

Arc welding parts

Complete range of arc welding parts for different purposes.

Flange joints

Wide range of flange joints such as loose flanges, SF flanges and HP flanges.

Custom pipe fittings

A range of customized pipe fittings is available for SLM® DCS. Also custom manufacture according to drawing.

Delivery options

Coil

Drum

Straight lengths

6, 12, 18, or 20 m

- All pipes are fitted with end caps

- Non-standard lengths can be ordered on request