Our products

Home » Multilayer pipes » SLA – Permeation resistant

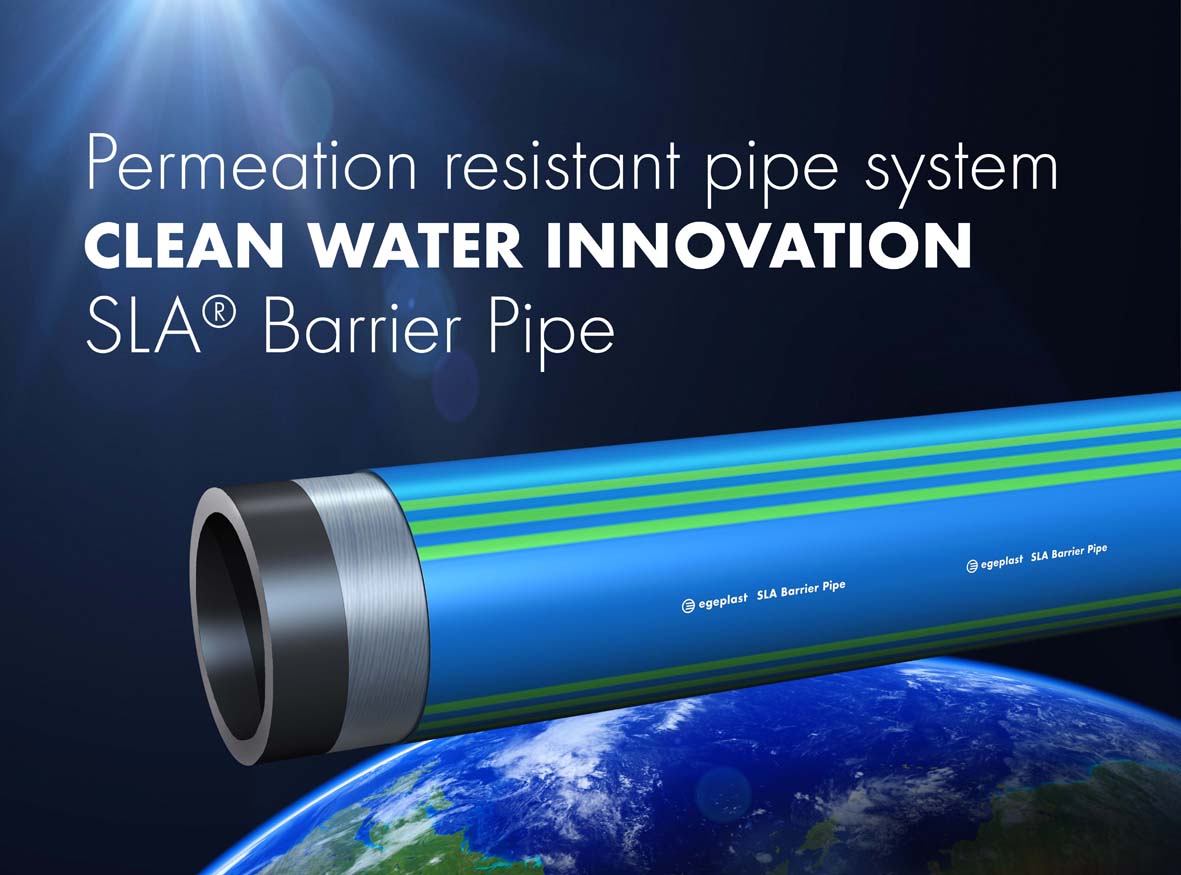

SLA® Barrier Pipe

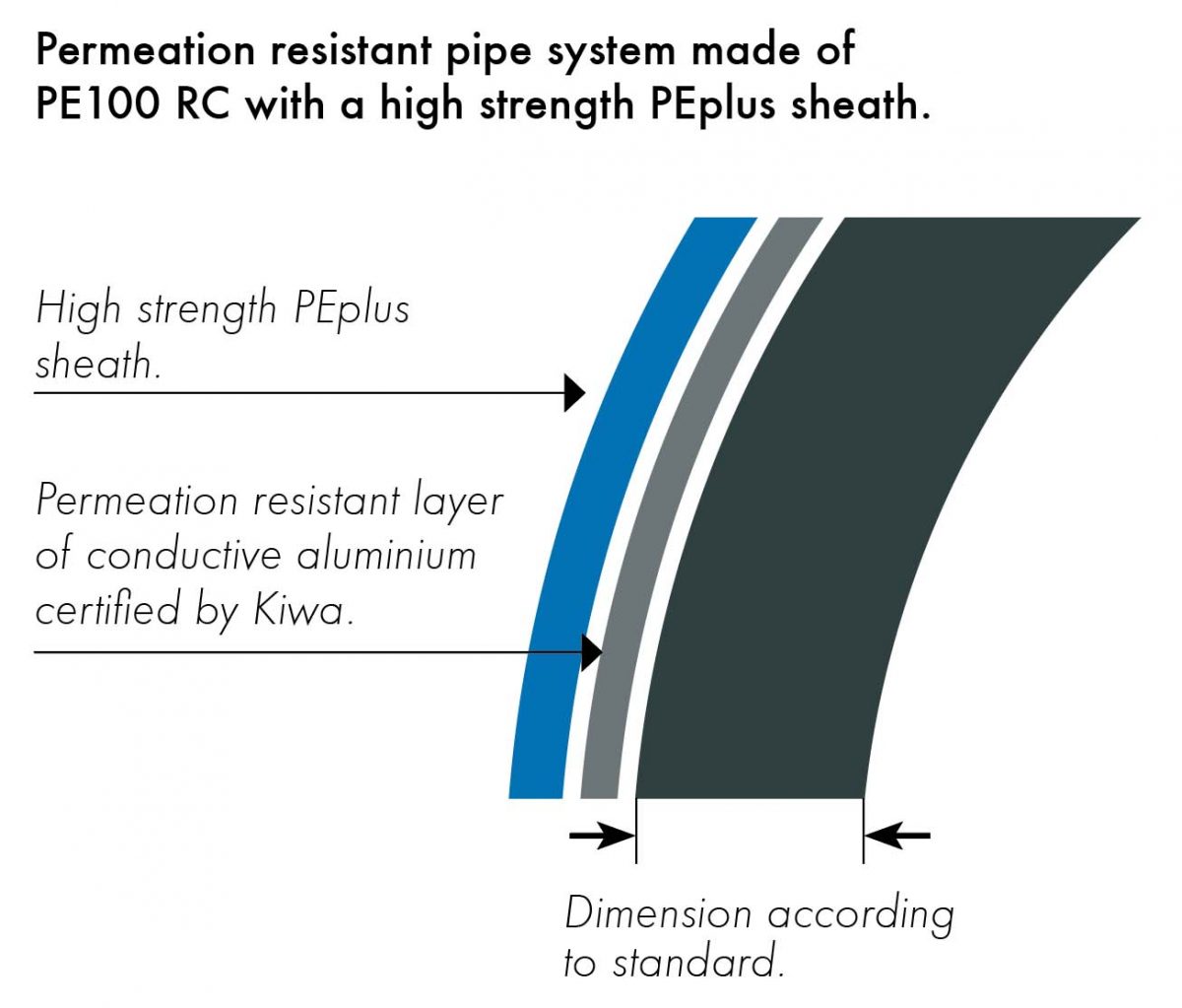

Permeation resistant pipe system made of PE100 RC for the protection of drinking water and the environment. Fitted with a high strength PEplus sheath. Dim ø 25-630 mm.

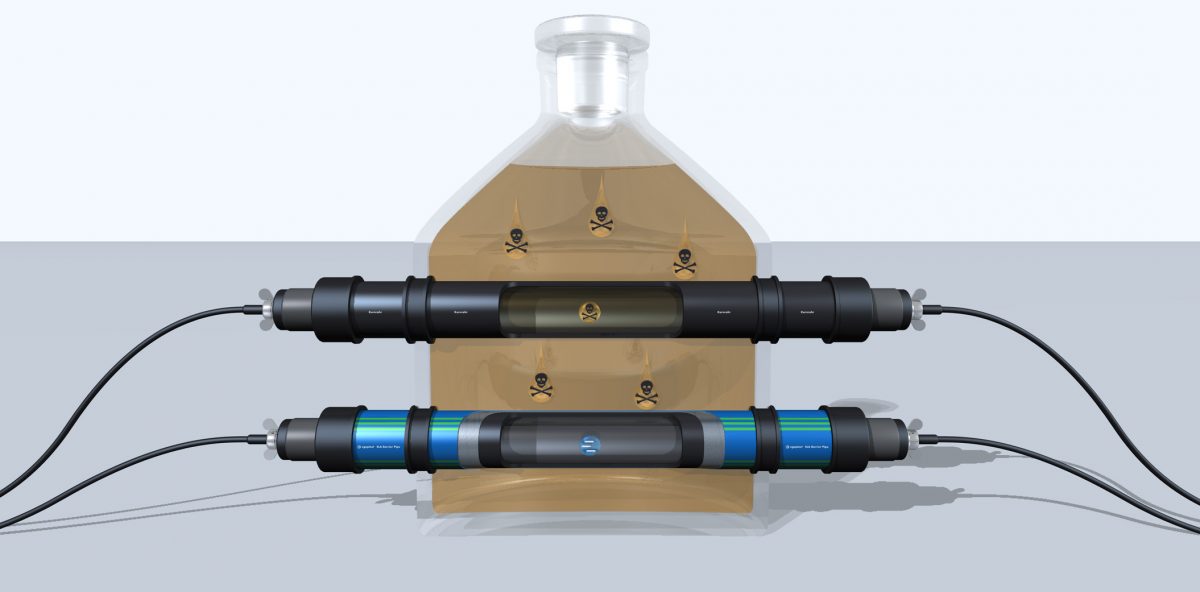

SLA® Barrier Pipe is a permeation resistant pipe system made of PE100 RC fitted with a high strength sheath and an impermeable barrier made of conductive aluminium to prevent the penetration of contaminants. The barrier provides permanent protection of both sensitive media and the environment.

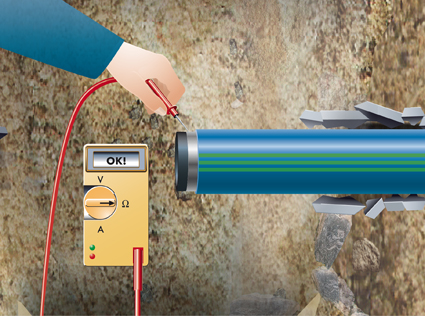

The conductive properties of the impermeable barrier also allow detection and stress measurement after installation to check that no damage has occurred during pipelaying. The design also allows precise location of the pipeline system, which facilitates future planning and excavation.

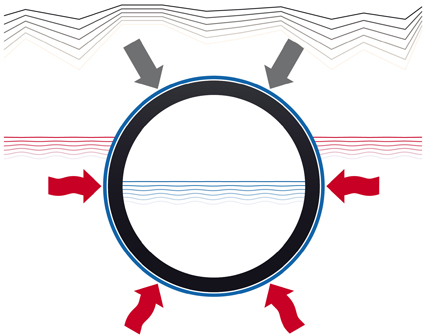

SLA® Barrier Pipe has the same properties as SLM® 3.0, but is also equipped with a permeation resistant aluminium barrier. This barrier works in both directions so the pipe protects the transportation of drinking water when laid in contaminated ground, as well as sensitive environments where the pipe transports waste water or other contaminated substances through or near a water source, for example.

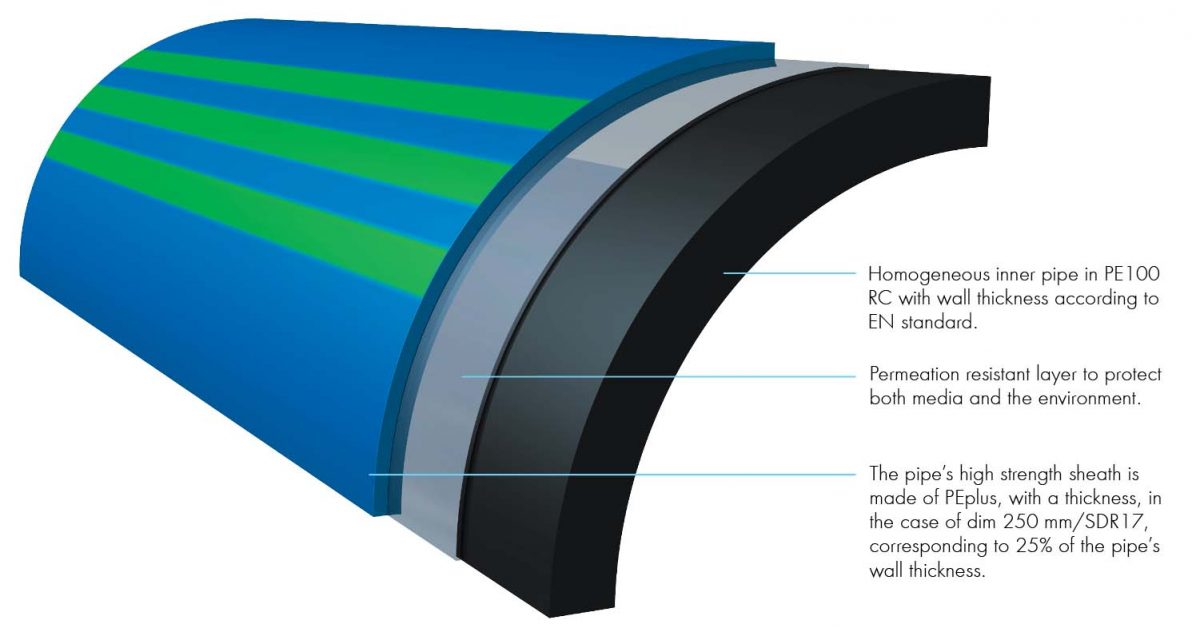

The pipe’s high strength sheath is made of PEplus, with a thickness, in the case of dim 250 mm/SDR17, corresponding to 25% of the pipe’s wall thickness. SLA® Barrier Pipe meets the requirements of PAS 1075 Type 3 (pipes with a higher strength sheath).

Certified impermeable barrier

KIWA is the institute that tests and issues certificates for permeation resistant barriers in polyethylene pipe systems.

The pipes are divided into two classes:

Class II For laying in ground where limited contaminants may occur that are higher than the limit values.

Class III For laying in ground where larger volumes of contaminants may be present.

3L® Leak Control is tested and certified according to the highest Class III.

For more information, download the PDF (1.6 MB) > (Evaluation Guideline BRL K-17101 2017-12-12 for the KIWA technical approval with product certificate for class II and class III polyethylene piping systems with an aluminium barrier layer for the transport of drinking water in polluted soil)

Protection of drinking water

In some areas, the media, such as drinking water in the pipeline, must be protected against contaminants in the ground.

Protection of sensitive environments

In some areas, the environment needs to be protected against contaminants in the media.

See the movie SLA® Barrier Pipe

Product benefits

- Permeation resistant pipe system made of PE100 RC for a safer service life and more efficient pipelaying.

- Impermeable barrier made of conductive aluminium.

- High strength PEplus sheath corresponding to e.g. 25% of the pipe’s wall thickness at dimension 250 mm/SDR17.

- Function check possible after pipelaying so that external pipe damage that occurred during pipelaying can be detected.

- Approved (Kiwa certified) for laying in contaminated soil.

- Minimal ovality for safe jointing.

- Complete range of pipe fittings.

Pipelaying method

Traditional pipelaying in trenches.

Traditional pipelaying adapted for pipes made of PE100 RC.

Function check after installation.

Also suitable for alternative installation methods.

Permeation resistant pipe system to protect both media and the environment.

Approvals/Certificates

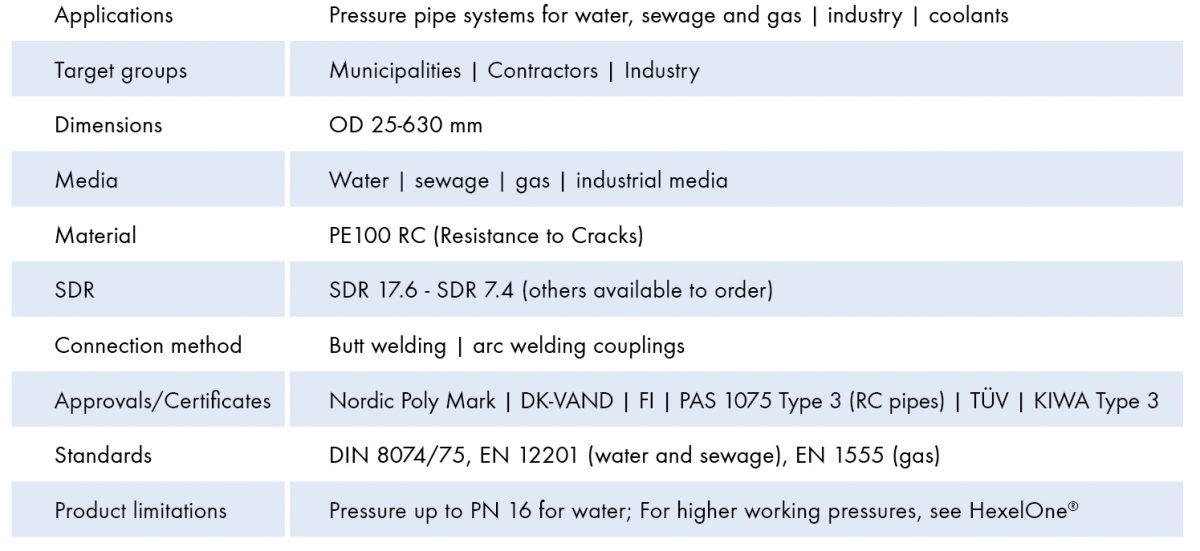

SLA Barrier Pipe is certified by KIWA (Class III) after long-term testing for impermeability and the effects of e.g. TCE (trichloroethylene).

Pipe systems must have a service life of at least 50 years. According to calculations, SLA Barrier Pipe can withstand penetration even after 100 years. Based on these tests and calculations, SLA has been certified by KIWA (BRL-K 170101).

Test rig (KIWA) used to test SLA Barrier Pipe together with homogeneous polyethylene pipes.

Facts

Pipe fittings

PE pipe fittings

– Injection moulded

– Seamless

– Machined

– Segment welded

Arc welding parts

Complete range of arc welding parts for different purposes.

Flange joints

Wide range of flange joints such as loose flanges, SF flanges and HP flanges.

Custom pipe fittings

Delivery options

Coil

Drum

Straight lengths

6, 12, 18, or 20 m

- All pipes are fitted with end caps

- Non-standard lengths can be ordered on request