Our products

Home » Multilayer pipes » 3L – With monitoring

3L® Leak Control with “online” function check

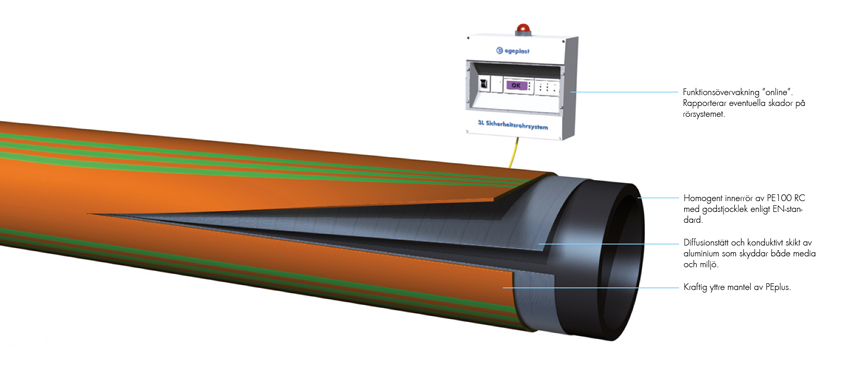

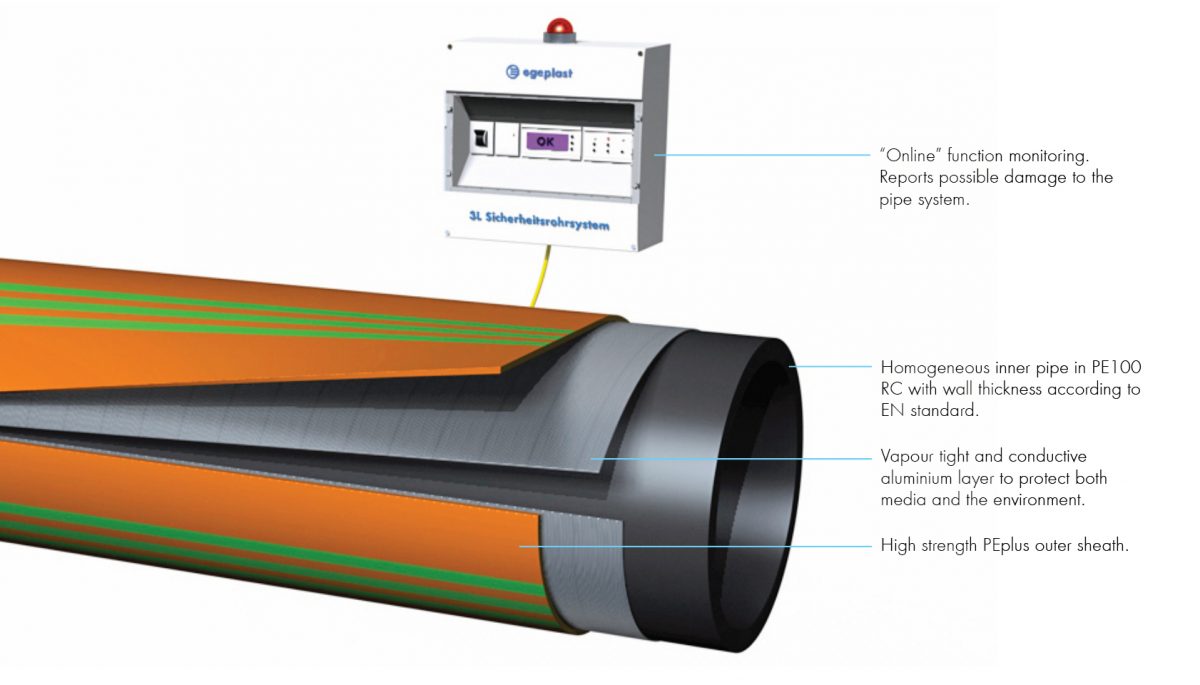

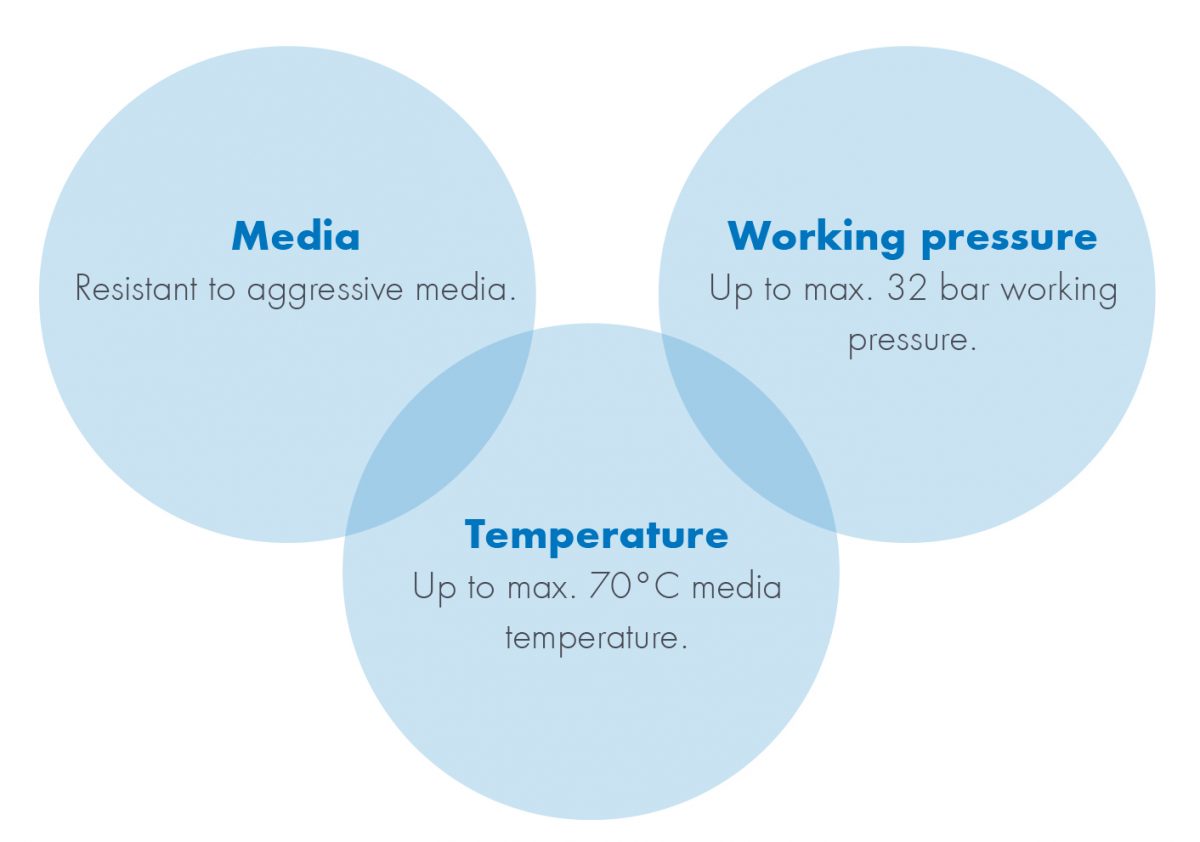

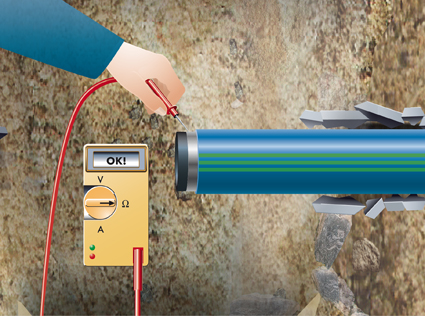

Permeation resistant pipe system made of PE100 RC for the protection of e.g. drinking water (media) or the environment. Fitted with a high strength PEplus sheath. A permanently monitored pipe system that detects and reports possible damage in real time.

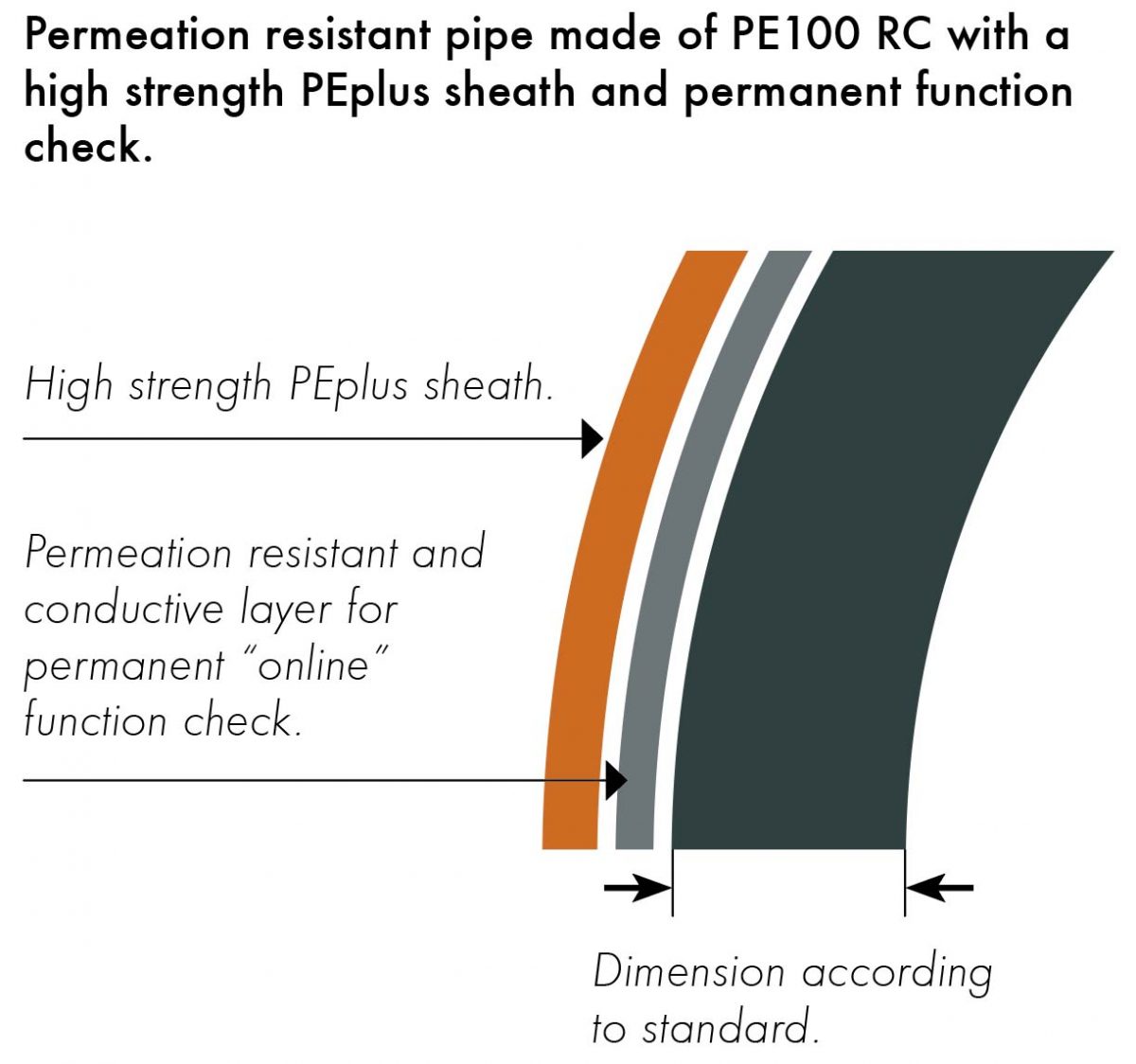

3L® Leak Control is a pipe made of PE100 RC equipped with a high strength PEplus sheath and an impermeable, conductive layer of aluminium that provides full control of possible leaks for optimal soil and water protection.

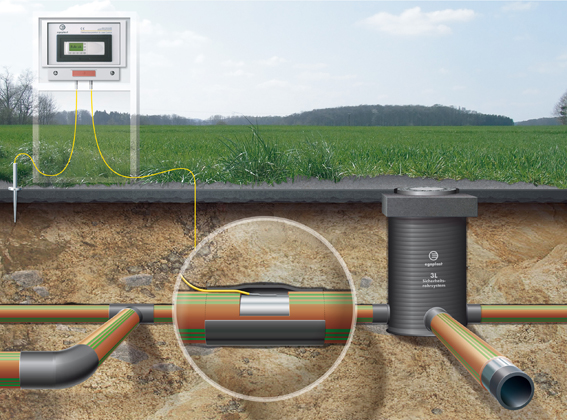

A monitoring device connected to the pipe issues an alarm even in the event of very minor pipe damage. The messages are then sent directly to the control centre or a mobile phone. The system can automatically shut down any connected pump systems, thereby preventing further impact caused by leakage at an early stage.

Permeation resistant and monitoring

In addition, the pipe’s intermediate layer, consisting of a conductive layer of aluminium, acts as an impermeable barrier that works in both directions. The pipe thus protects the transportation of drinking water when laid in contaminated ground, as well as sensitive environments where the pipe transports waste water or other contaminants through or near a water source, for example.

Extra protection against scratches and point loads

The pipe’s high strength sheath is made of PEplus, with a thickness, in the case of dim 250 mm/SDR17, corresponding to 25% of the pipe’s wall thickness. In addition to protecting against scratches and pipe damage caused during pipelaying, the high strength sheath also helps to distribute the pressure from any point loads over a larger surface, thereby reducing impact on the main pipe. If necessary, the sheath material can be adapted to a specific application. 3L® Leak Control meets the requirements of PAS 1075 Type 3 (pipes with a higher strength sheath).

Complete system with pipes, pipe fittings and wells

3L® Leak Control includes a wide range of pipe dimensions, from 25 mm to 1200 mm in diameter. The complete system also includes customized pipe fittings and wells, as well as modern measuring technology for the rapid detection of possible pipeline damage. In Germany, the 3L® Leak Control pipe system meets the requirements for continuous leak monitoring according to ATV-DVWK-A 142 for use in connection with water source (drinking water) protection zone II with a high risk potential. However, similar standards do not yet exist in the Nordic market.

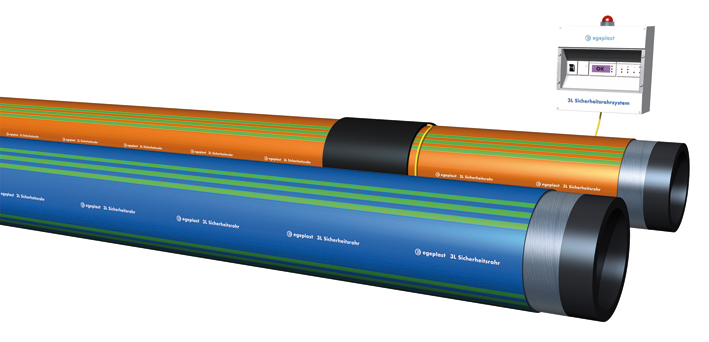

3L® Leak Control with online monitoring of damage and leakage with automatic shut-off

Protection of the environment

3L® is designed to protect the environment during the transportation of contaminated sewage. For example, when sewage water is to be routed through a water source or sensitive environment.

Protection of drinking water

3L® is the best choice for industries that want full control of their pipeline network

Extena 3L® is the best choice for industries that want full control of their pipeline network

Industries handling hazardous substances are concerned that they do not leak into the ground. As a result, more and more industries are choosing to install 3L® with online monitoring so that even minor leaks can be detected and corrected immediately. This minimizes the risk of future clean-up work and leakage of environmentally hazardous substances into the environment.

3L® Leak Control is certified by KIWA, Class III (highest class) after long-term testing for impermeability and the effects of e.g. TCE (trichloroethylene). Pipe systems must have a service life of at least 50 years. According to calculations, 3L® Leak Control can withstand penetration even after 100 years. Based on these tests and calculations, 3L® has been certified by KIWA (BRL-K 170101).

Certified permeation resistance

KIWA is the institute that tests and issues certificates for impermeable barriers in polyethylene pipe systems.

The pipes are divided into two classes:

Class II For laying in ground where limited contaminants may occur that are higher than the limit values.

Class III For laying in ground where larger volumes of contaminants may be present.

3L Leak Control is tested and certified according to the highest Class III.

For more information, download the PDF (1.6 MB) > (Evaluation Guideline BRL K-17101 2017-12-12 for the KIWA technical approval with product certificate for class II and class III polyethylene piping systems with an aluminium barrier layer for the transport of drinking water in polluted soil).

Product benefits

- Pipe system made of PE100 RC for a safer service life and more efficient pipelaying.

- The pipe is equipped with a conductive layer of aluminium for permanent “online” pipeline monitoring and accurate leak detection.

- 3L® Leak Control is a complete system for monitoring a pipe system “online”.

- High strength PEplus sheath corresponding to e.g. 25% of the pipe’s wall thickness at dimension 250 mm/SDR17.

- A pipe system suitable for use in environments where full “online” control of possible pipe damage is required.

- Safe welding connections according to DVS 2207.

- Minimal ovality for safe jointing.

- Complete range of pipe fittings.

Pipelaying method

Traditional pipelaying in trenches and adapted for pipes made of PE100 RC.

Permanent function check that reports possible damage.

Also suitable for alternative installation methods.

Permeation resistant pipe system to protect both media and the environment.

Function check after installation.

Approvals/Certificates

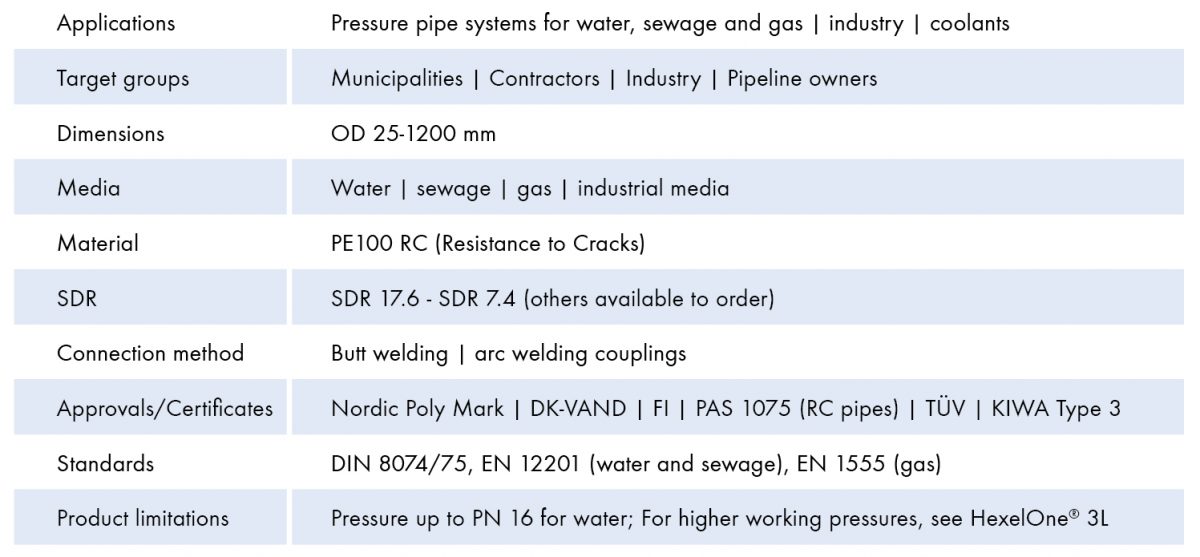

Facts

Pipe fittings

PE pipe fittings

– Injection moulded

– Seamless

– Machined

– Segment welded

Arc welding parts

Complete range of arc welding parts for different purposes.

Flange joints

Wide range of flange joints such as loose flanges, SF flanges and HP flanges.

Custom pipe fittings

Delivery options

Coil

Drum

Straight lengths

6, 12, 18, or 20 m

- All pipes are fitted with end caps

- Non-standard lengths can be ordered on request