Home » Manufacturing & Quality » PE100-RC

This is why we have chosen to manufacture virtually all our pipes in PE100 RC

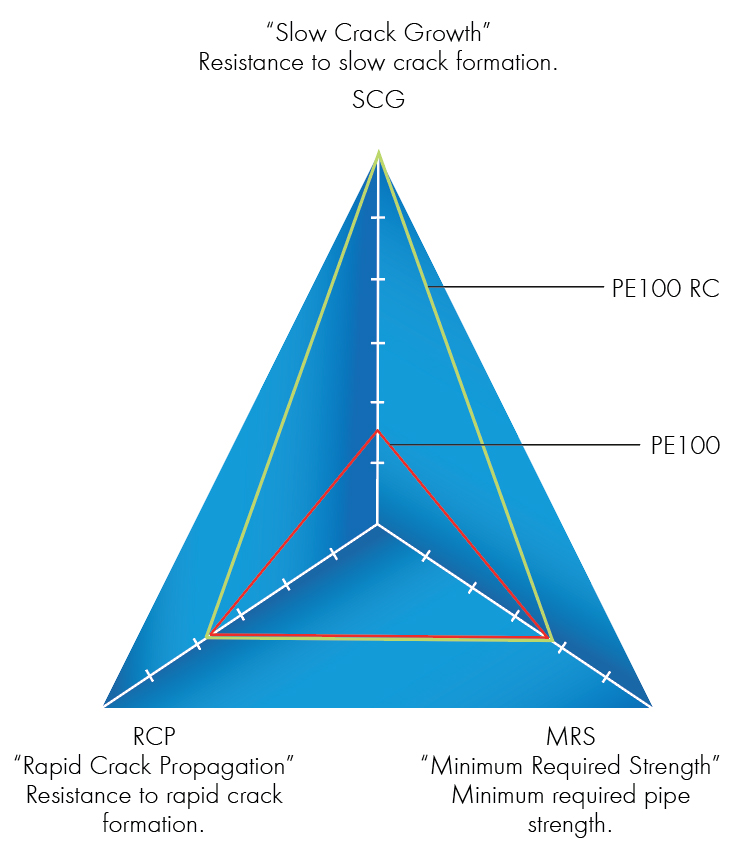

Polyethylene (PE) is lightweight and durable and has been the dominant raw material in pressure pipe systems for decades. The material, which provides reliable systems for the safe transportation of drinking water, waste water and process water, has been developed and launched in a number of versions over the years. As the demands for more cost effective pipe systems are constantly increasing, the material PE100 RC was launched in 2005 with more and stronger bonding between the molecules. The result is a raw material and pressure pipe system with significantly higher resistance to slow crack growth. We therefore recommend that you always choose pipes made of PE100 RC, which provides a safer and more cost effective pipe system.

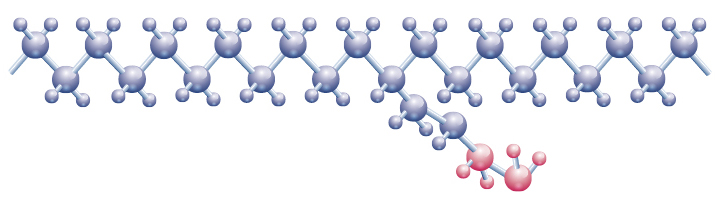

More bonding molecules

PE100 RC is polymerized with hexene instead of butene, which is often used for traditional PE. Hexene is an alkene with long molecules, which strengthen the bond in a molecular chain. The bonding molecules make the RC material stronger, but above all they retain the structure of the crystalline regions. The PE polymer is thus designed for maximum mechanical resistance to slow crack growth (SCG).

More facts about polyethylene and PE100 RC

New alternative installation methods and maximum service life requirements require pipes made from the best possible raw material. Extena’s PE100 RC material, certified according to PAS 1075, has 17 times higher requirements for resistance to slow crack growth (SCG) compared to the materials that the Swedish AMA (General material and work descriptions) bases its recommendations on. By choosing PE100 RC, you will not only have pipe systems with maximum service life, but also faster and more cost effective pipelaying.

Read more about polyethylene and PE100 RC in our brochure.