Round pipes are essential for secure jointing

We therefore have higher requirements than the standards to ensure minimum ovality.

The joints are most often the weak link in the pipe system. One of the more important requirements from contractors and pipeline owners, therefore, is good conditions for safe jointing. In order to produce safe joints, the pipes must be of high quality in all respects, both in terms of raw materials and the manufacturing process. Round pipes with low ovality are an important part of this.

We have 40% higher requirements in terms of ovality than specified in the standard!

During manufacture of a PE pipe, stress is created in the pipe wall when the pipe is cooled down. This built-in stress causes the ends of the pipes to bend into the pipe when they are cut, known as toe-in. This phenomenon, as well as stacking and storage, affects the ovality of the pipe.

To eliminate the effect of bending in, Extena uses a unique method where the pipes are cooled down over a longer period and stabilized during the cooling process. The pipes are then stored in a cassette where they are allowed to cool before being bundled.

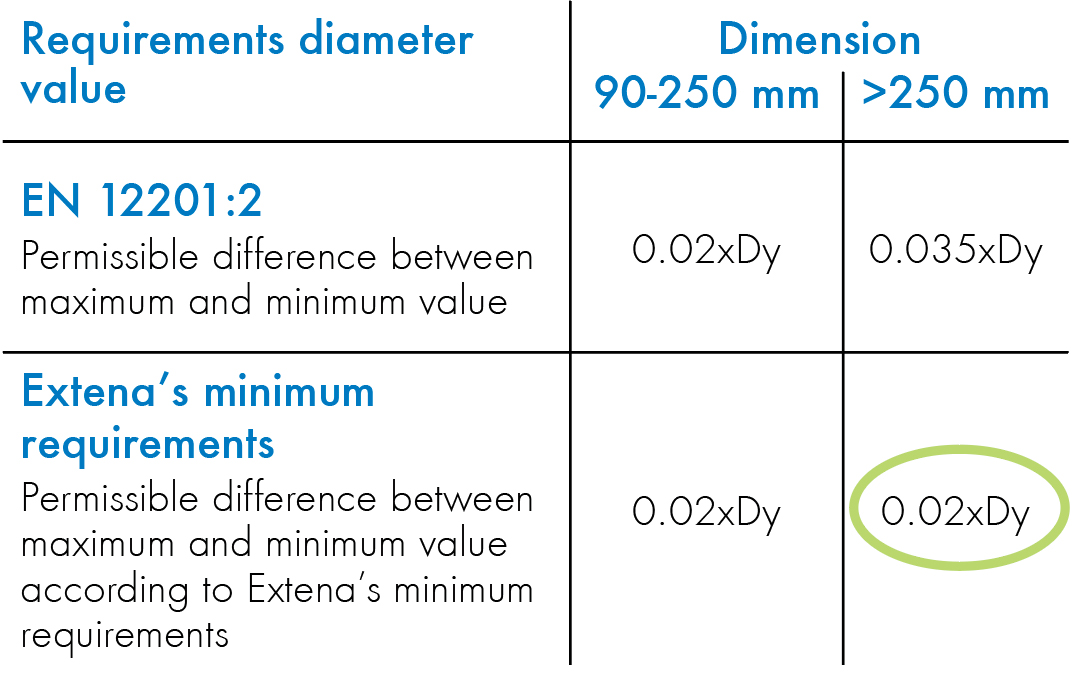

We have therefore been able to set higher requirements and significantly tighter tolerance levels for ovality than the standard allows. We have the same requirements for pipes in dimensions over 250 mm as specified by the standard for pipes in dimensions between 90-250 mm (see table).

To eliminate the effect of bending in, Extena uses a unique method where the pipes are cooled down over a longer period and stabilized during the cooling process. The pipes are then stored in a cassette where they are allowed to cool before being bundled.

We have therefore been able to set higher requirements and significantly tighter tolerance levels for ovality than the standard allows. We have the same requirements for pipes in dimensions over 250 mm as specified by the standard for pipes in dimensions between 90-250 mm (see table).