Our products

Home » Cable protection pipes

Cable protection SRS, SRE-P and SRS with power cable

and for optical fibre

Cable protection pipe made of polyethylene PEHD. Available in three versions: SRS and SRE-P, SRS with predrawn power cable and cable protection for optical fibre. Dim ø 50-315 mm

We offer cable protection pipes for class SRS and SRE-P. SRS (protection, pipes, difficult conditions) is our standard pipe that complies with SPF work standard 5200 and SP Technical Research Institute of Sweden’s inspection guidelines SPKB 1992:06, while SRE-P (protection, pipes, extra difficult conditions – plastic) is used for surface laying in difficult terrain. Our SRE-P pipes are manufactured according to SS 424 14 37. Both pipes are manufactured from high density polyethylene (PEHD).

Extena’s SRS and SRE-P cable protection pipes have a grooved interior to reduce friction when pushing through power cables. We see this as a big advantage. The use of cable protection pipes instead of a sand bed also provides more efficient propulsion, safer pipelaying and lower total costs.

Cable protection pipe SRS is also available with predrawn power cable N1XE-AR 4G25. We also offer cable protection pipes for optical fibre in standard dimensions and in the special dimension 40/29 with extra high ring stiffness.

Higher ring stiffness than standard

This is a big difference in the quality and ring stiffness of the cable protection pipes available on the market. The standard for the ring stiffness of cable protection pipe SRS is 8 kN, which in our opinion is far too low for pipelaying without a sand/rock flour bed. To ensure a long and safe service life, we manufacture our pipes with a ring stiffness of over 16 kN, in other words significantly higher than the standard.

Be aware that low price pipes are imported into the market that exactly meet the requirements for ring stiffness. There is a risk that these pipes will not withstand stress over time. However, with Extena cable protection pipes you can be sure that you will get a secure system with a long service life.

Quality at every stage

Our products undergo very thorough quality control, both in our own testing laboratory and at external inspection institutes. In this important task, we collaborate closely with the research Institute RISE. Another aspect of our quality assurance is that we have full traceability of the materials that we use.

Unique grooved interior significantly reduces friction and facilitates cable pushing.

Pipes for rough terrain

Our cable protection pipes are specially designed for tougher terrain where high strength is a requirement. They are manufactured from high density polyethylene (PEHD) and have a ring stiffness (over 16 kN) that is significantly higher than standard requirements (8 kN). The pipes have a high resistance to external pressure and stress and are also resistant to most chemicals. They are also sealed to prevent the penetration of ground water and soil or sand. Quite simply, Extena’s cable protection pipes provide highly reliable protection for electrical cables – and thus offer optimal weather protection.

Extena Prefab Kraft. SRS-rated cable protection pipe with predrawn power cable (4G25 AL).

Cable protection pipes for optical fibre are also available in dim 40/29 with an extra high strength wall thickness (5.5 mm) for demanding environments with higher stress.

Cable protection pipes SRS and SRE-P for power cables.

Extena offers cable protection pipes for both SRS and SRE-P. SRS (protection, pipes, difficult conditions) is our standard

pipe that complies with SPF work standard 5200 and SP Technical Research Institute of Sweden’s inspection guidelines SPKB 1992:06, while SRE-P (protection, pipes, extra difficult conditions – plastic) is used for surface laying in difficult terrain. Our SRE-P pipes are manufactured according to SS 424 14 37. Both pipes are manufactured from high density polyethylene (PEHD).

Extena Prefab Kraft. SRS-rated cable protection pipe with predrawn power cable.

Extena Prefab Kraft is an SRS-rated cable protection pipe with a predrawn power cable designed primarily for utility services in buildings, but is also used as a problem solver for other applications such as repairs and temporary installations. Extena Prefab Kraft make installation easier as the power cable is already installed in the cable protection pipe. The result is fast, efficient and easy pipelaying. Prefab Kraft is manufactured at our factory in Norsjö and is supplied with a dimension of 50 mm in lengths of 250 metres on a K16 drum. The SRS pipe is also approved for temporary open pipelaying.

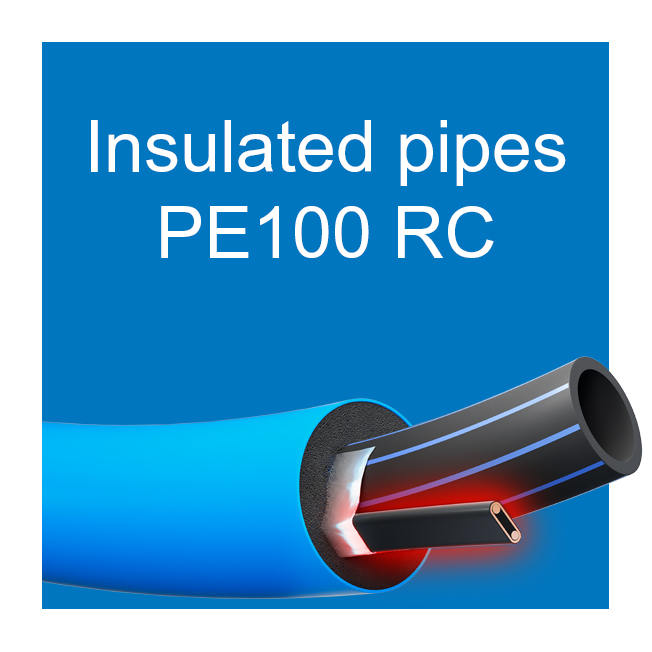

Optical fibre

For over 20 years, Extena has manufactured and supplied optical fibre ducting for the expansion of infrastructure throughout Sweden. Extena Cable Protection Opto is a low friction pipe with a smooth interior that can also be ordered with a silicone coating, allowing the installation of several kilometres of optical fibre cable, either by injecting air or by flushing with water.

In addition to the standard pipe, Cable Protection Opto is also available in dimension 40/29, a special dimension with extra high ring stiffness for a safe service life in demanding environments. This product is designed primarily for wind farms and for joint pipelaying projects in rough terrain along with SRS. Demand for dimension 40/29 has increased sharply in recent years.

Product benefits

- Cable protection pipe SRS, SRE-P made of PEHD.

- Extena cable protection pipes have a higher ring stiffness than specified in the standard. Over 16 kN instead of 8 kN.

- The pipes have a grooved interior for reduced friction and easier pushing through.

- The use of cable protection pipes instead of a sand bed provides more efficient propulsion, safer pipelaying and lower total costs.

- Cable protection pipe SRS is also available with a predrawn power cable for more efficient installation.

- Cable Protection Opto can also be ordered with a silicone-blended internal coating, which reduces friction between the fibre cable and pipe wall.

- Extena also offers Cable Protection Opto in special dimension 40/29 with higher ring stiffness for demanding environments.

Pipelaying method

Traditional pipelaying in trenches.

Suitable for trench-free pipelaying.

Approvals/Certificates

SPF work standard 5200 issue 1 – EBR standard KJ41:15 – SPKB 1992:06

Facts

Pipe fittings

PE pipe fittings

– Injection moulded

– Seamless

– Machined

– Segment welded

Arc welding parts

Complete range of arc welding parts for different purposes.

Delivery options

Coil

Drum

Straight lengths

6, 12, 18, or 20 m

- All pipes are fitted with end caps

- Non-standard lengths can be ordered on request