Pipe systems for water & sewage

Gas transportation can have devastating consequences for both humans and the environment in the event of a leakage or breakdown. The transportation of gas is therefore a highly controlled area requiring certified pipes of the highest quality and traceability of both product and raw material.

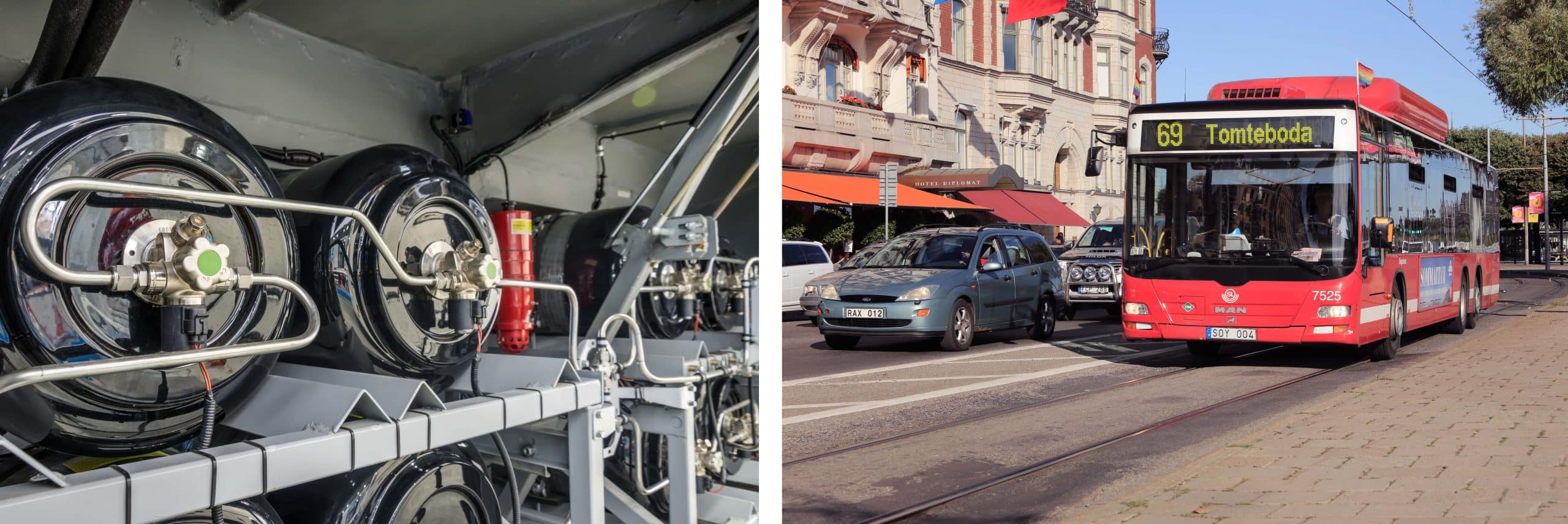

Our gas pipes are used for the transportation of e.g. natural gas and biomethane.

Extena was quick off the mark to develop systems for maximum control and traceability and today offers Inspection certificate 3.1 according to EN 10204 for customers who require it. Our traceability makes it easy to trace e.g. suppliers of raw materials, pipes and pipe fittings, including the extrusion line and date of manufacture. The aim is to ensure that our customers are confident in their choice and know that their gas pipelines are of the highest quality.

We offer pipes for gas pipelines installed in trenches (standard pipe 90/10) as well as for alternative installation methods (SLM®). Our range of gas pipes also includes the unique multilayer pipe HexelOne®, which can withstand a gas pressure of 16 bar. We can also offer pipes and pipe fittings from the same batch and with 3.1 certificates.

Our gas pipes are manufactured according to standard SS-EN 1555 and meet the requirements of the Swedish Gas Association standard EGN 2020 and AFS 216:1.

• Gas can be fatal

• Gas pipelines with maximum control

• High traceability

• EN 10204 Inspection certificate 3.1

• EN 1555

• Option to order pipes and pipe fittings from the same batch

The standard pipes are supplied in two designs. Either with stripes or with approx. 10% of the pipe’s wall thickness (outer layer) in a different colour (pipe 9010®) to allow you to locate and assess any scratches that have occurred during pipelaying. According to AMA, scratches and external damage to PE pipes may not exceed 10% of the pipe´s wall thickness. With our colour layer, which makes up approx. 10% of the pipe’s wall thickness, you can easily see if a scratch is deeper than approx. 10%.

Inspection certificate 3.1 according to EN 10204

The manufacture of gas pipes is defined in various standards and directives such as EN 1555. SS-EN 10204 is a European standard that regulates the design of Inspection certificate 3.1. We can supply pipes with Inspection certificate 3.1 according to EN 10204 for customers who require it.

Extena gas pipes with Inspection certificate 3.1 according to EN 10204 meet the requirements of the Swedish Work Environment Authority’s Regulations AFS 2016:1 “Pressure Equipment” and the Swedish Gas Association standard EGN 2020.

Please state at the time of quotation and ordering if an Inspection certificate 3.1 is required.

Swedish Gas Association and EGN 2020

Extena is a member of the Swedish Gas Association (Energigas Sverige), an organization for stakeholders in the energy gas industry. Members of the association include grid operators, gas suppliers, manufacturers and suppliers of gas equipment, installation companies, consulting companies, etc. Grid operators that are members of the Swedish Gas Association have undertaken to comply with these standards.

A central part of the association’s activities is to promote the safe use of energy gases (natural gas, biogas, LPG, vehicle gas and hydrogen). This involves drawing up standards and instructions. The regulations up to 4 bar for natural gas, biogas and LPG in the gas phase are coordinated in EGN 2020.

The construction, inspection and operation of distribution systems for gas, natural gas, biogas and LPG in the gas phase as well as associated installations according to EGN ensure compliance with the reasonable precautions clauses of the legislation on flammable and explosive materials.