Clean water

for future

generations

Our products

Why is PE100 RC the best raw material?

We ask Extena’s new product manager Anders Mattsson why it is important to choose pressure pipes made of PE100 RC.

Why is it important to choose pressure pipes made of PE100 RC?

The RC material, where RC stands for “Resistance to Crack”, has 17 times higher requirements for slow crack growth compared to regular PE100 material. Quite simply, the material has more bonding molecules, which significantly increases the resistance to slow crack growth. Slow crack growth is usually the most significant impact on the life of a pipe.

Why is slow crack growth so dangerous?

If the surface of a pressure pipe is damaged during transport or laying, there is a risk that the pipe will eventually crackle under pressure from inside and/or from the backfill material. There are several studies that show that failures in pressure pipelines are often caused by a crack growing over a long period of time through the pipe wall. This slow crack growth can be greatly reduced – and even eliminated – by choosing RC material instead of traditional PE100.

Does the choice of PE100 RC also influence pipelaying?

Yes it does. You usually get faster propulsion, allowing a higher fraction in the backfill material, up to 50% of the pipe diameter, max. 64 mm. However, our recommendation is to always use normal backfill under and around the pipe itself, which according to AMA must be 0–32 mm in the support packing zone. Being able to use existing aggregate to a greater extent also allows you to achieve better overall cost efficiency.

How does the choice of PE100 RC affect pipe life?

Tests show that pressure pipes made of PE100 RC are significantly better placed to achieve a service life of over 100 years. The RC material has 17 times higher requirements for slow crack growth compared to regular PE100 material, which is confirmed by a variety of tests.

You have been working with plastic pipes for over 30 years now, most recently as sales manager at Extena, and are now taking on the position of product manager. What is the most important thing to consider when purchasing a pipe system?

You should always choose a pipe system that is safe and easy to install. It is also important that the system is manufactured from the best raw material. When it comes to the laying of a pipe system, the pipes themselves represent a relatively low percentage of the cost, in most projects just 5 to 15% of the total cost. By choosing PE100 RC, for example, you will achieve faster propulsion, and a longer and safer service life resulting in better overall cost efficiency. This will also ensure safer pipeline ownership.

Our own requirement at Extena is that a pipe system should have a service life of at least 100 years.

Anders Mattsson, new product manager

Extena uses PE100 RC with 17 times higher requirements for slow crack growth.

See our large catalog in English of polyethylene pipe systems

In addition to presenting the market’s widest range of polyethylene pipe systems, we also discuss quality tests that exceed the standard, PE100 RC, multilayer pipes and what the requirements are for safe jointing.

Download (13,6 Mb)

Request a printed copy

Browse online

PE100 RC

-the best choice

Safe supplier

for large

projects

Expert in multilayer pipes

Higher requirements than the standards

Latest news

Our three unique pressure pipes made of PE100 RC

Here you can see our three standard pressure pipes. These are basically the same media pipe but with additional properties and functions. Some with a high strength protective sheath and some with an impermeable barrier. Once you have chosen one of the three basic designs, you can add additional features and functions as required.

1.

✔ Standard pipe PE100 RC

Standard Pipe PE100 RC

Our standard pipe made of PE100 RC, the best raw material on the market with 17 times higher requirements for slow crack growth.

Read more >

Plus outer layer in a different colour for damage assessment:

Standard Pipe 90/10

We have made our standard PE100 RC pipe with about 10% of the outer layer in a different colour, which makes it easy to assess whether any damage has occurred during pipelaying. Being able to make an accurate assessment is particularly important in the case of pipes intended for gas, for example. Like all our standard pipes, the pipe is completely homogeneous.

Read more >

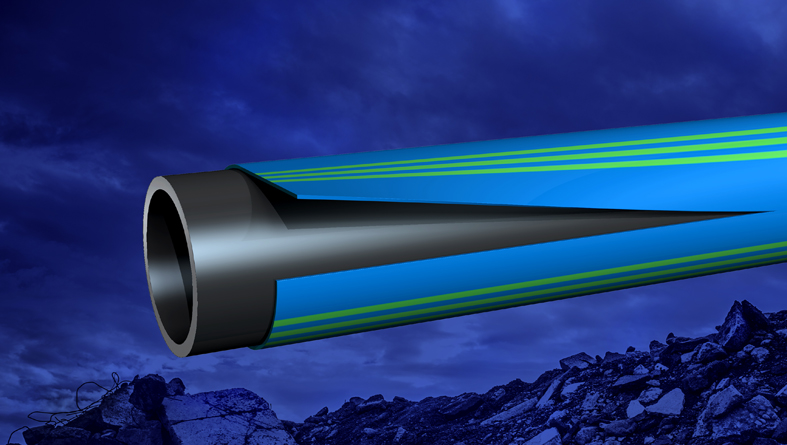

2.

✔ Standard pipe PE100 RC

✔ High strength protective sheath

SLM® Protected Pipe

Our standard PE100 RC pipe fitted with a high strength PE sheath corresponding to 25%* of the pipe’s wall thickness. Read more >

*Example dim 250 mm/SDR 17

Plus installation check:

SLM® DCT

By fitting the pipe with conductive strips, a function check can be carried out after installation to ensure that the pipe is intact and no damage has occurred. Read more >

Plus online function check:

SLM® DCS

Pipes with a sheath and conductive strips (SLM® DCT) can also be fitted with continuous monitoring and function checks.

Read more >

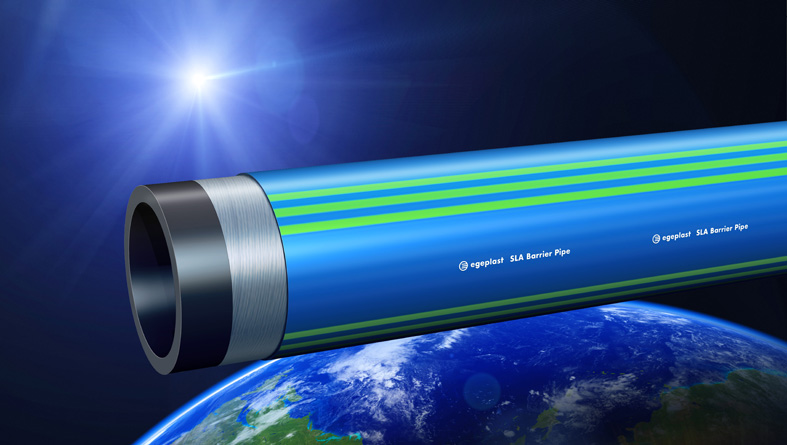

3.

✔ Standard pipe PE100 RC

✔ High strength protective sheath

✔ Impermeable barrier

SLA® Barrier Pipe

Our standard PE100 RC pipe fitted with a high strength PE sheath and a solid aluminium impermeable barrier to prevent the penetration of unwanted substances.

Read more >

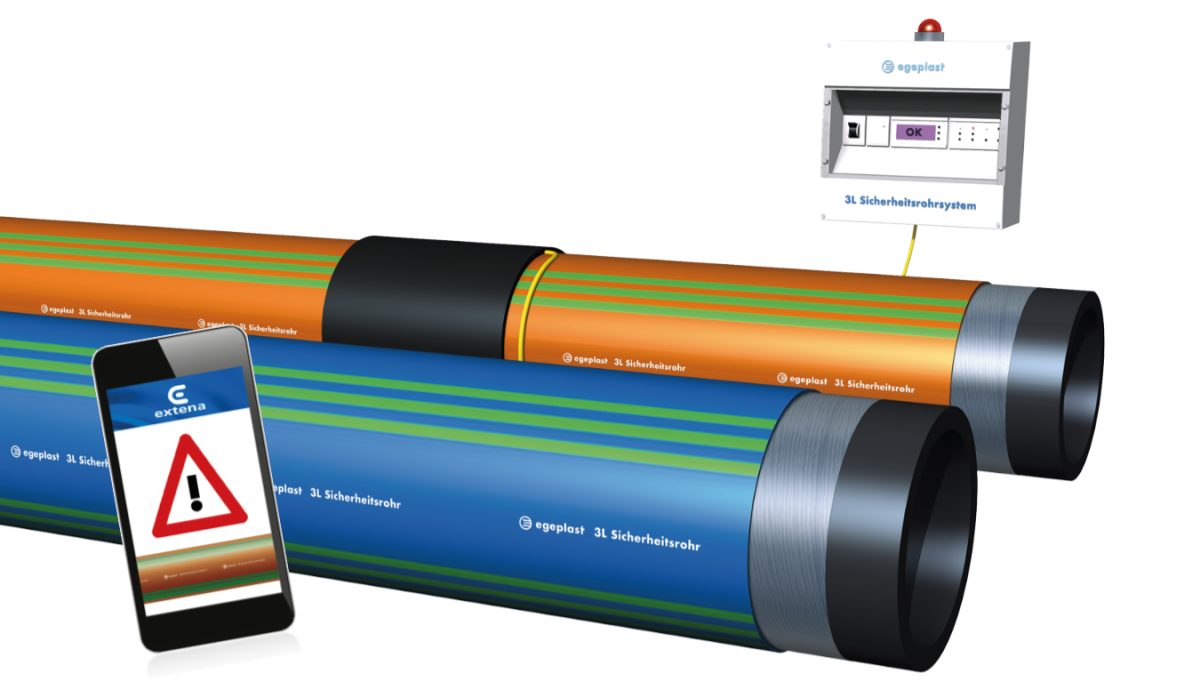

Plus online monitoring and damage localisation:

3L® Leak Control

This is our safest pipe system by far. The PE100 RC media pipe is fitted with a high strength PE sheath and an impermeable barrier. The pipeline is connected to a continuous monitoring device that detects and reports damage in real time. The system automatically alerts you when pipe damage occurs.

Read more >

3L® Leak Control is the safest pressure pipe system on the market

– also suitable for gravity pipes with very high requirements

The need to transport water and pollutants safely is constantly increasing. Any leaks on the grid can have catastrophic consequences – if not detected in time.

3L Leak Control is a pipe made of PE100 RC equipped with a high strength PEplus sheath and an impermeable, conductive layer of aluminium that provides full control of possible damage and leaks for optimal soil and water protection.

A monitoring device connected to the pipe issues an alarm even in the event of very minor pipe damage. The system can automatically shut down any connected pump systems, thereby preventing further impact caused by leakage at an early stage.

Read more about 3L® Leak Control >

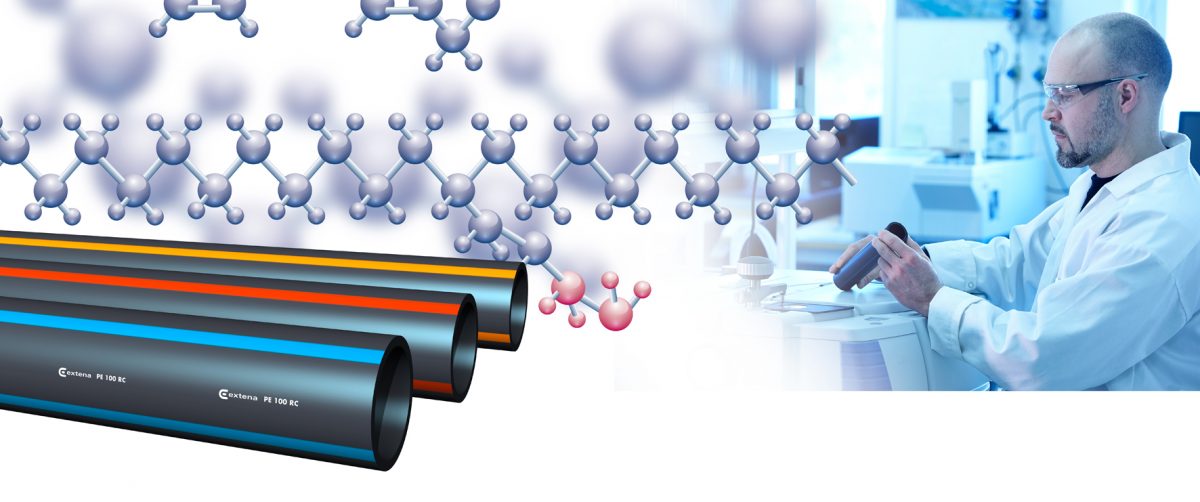

This is why we have chosen to manufacture virtually all our pipes in PE100 RC

– it is the safest and best raw material on the market at 17 times higher than standard requirements

A long service life requires the best raw material

As the demands for more cost effective and safer pipe systems are constantly increasing, the material PE100 RC (RC stands for Resistance to Cracks) was launched in 2005 with more and stronger bonding between the molecules. The result is a raw material and pressure pipe system with significantly higher resistance to slow crack growth (SCG).

We therefore recommend that you always choose pipes made of PE100 RC, which provides a safer and more cost effective pipe system.

More bonding molecules

PE100 RC is polymerized with hexene instead of butene, which is often used for traditional PE. Hexene is an alkene with long molecules, which strengthen the bond in a molecular chain. The bonding molecules make the RC material stronger, but above all they retain the structure of the crystalline regions. The PE polymer is thus designed for maximum mechanical resistance to slow crack growth (SCG).

Read more about Polyethylene PE100 RC >

Extena is Sweden’s leading supplier of cable protection pipes SRS and SRE-P

Extena is leading the development and manufacture of cable protection pipes SRS and SRE-P in Sweden, a position that has been achieved through our long-term focus on innovation and quality. We have chosen to specialize in a few carefully selected key products, such as SRS, SRE-P, Prefab Kraft (SRS with predrawn power cable) and cable protection pipes for optical fibre in two thicknesses, to ensure the highest quality at all stages.

We are also the country’s leading supplier of cable protection pipes on coils. Our products have a higher ring stiffness than standard requirements and the pipes offer both more efficient laying, lower total costs and a safer service life compared to traditional laying of power cables in a sand bed.

Read more about Extena cable protection pipes >

Stay up-to-date – sign up for our newsletter!

Our newsletter will keep you up to date with news, exciting pipe projects and other interesting information about polyethylene pipe systems from leading manufacturers in the market.

Specialists

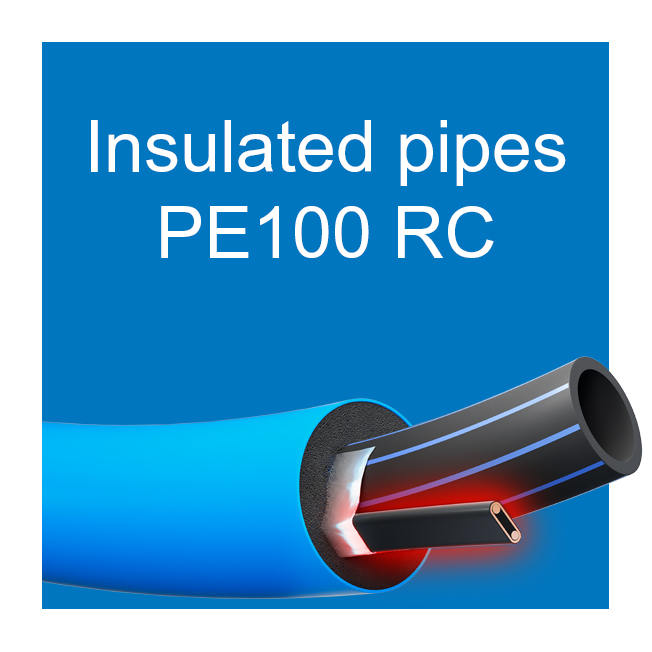

We are specialists in the extrusion of thermoplastic pipes and one of the leading companies in the Nordic region supplying PE100 RC pressure pipes, multilayer pipes, cable protection pipes, insulated pipes and special pipes for different purposes. We are at the very forefront when it comes to using developed raw materials, PE100 RC being a good example.

Accessible

Key success factors are our long experience and our commitment to always be as accessible and as close as possible to our customers. Today we use advanced manufacturing and development technology. Extena is a safe partner throughout the procurement process as well as the design phase.

Professional experience

Our company history dates back to the 1970s. Our employees possess a broad and high level of competence. Since April 2020, Extena is part of the German group egeplast, which for decades has been Europe’s leading manufacturer of polyethylene pressure pipe systems in general and multilayer pipes in particular.

Contact us

We will be happy to help you. Please fill out the form below and we will contact you shortly. Of course, you can also call us or send us an email.

Anders Rydén

Sales Water and Sewage southern Sweden and Finland

Telephone +46 (0)706 17 90 09

Thomas Hammarberg

Sales Water and Sewage northern Sweden

Telephone +46 (0)705 43 43 57

Email

thomas.hammarberg@extena.se

Edde Johansson

Sales Cable Protection

Telephone +46 (0)706 10 54 20

Tomas Nordin

Sales Director/CSO

Telephone +46 (0)705 23 33 73