Menu

Our products

Menu

Home » Multilayer pipes » SLM® DCT – With sheath and built-in function test

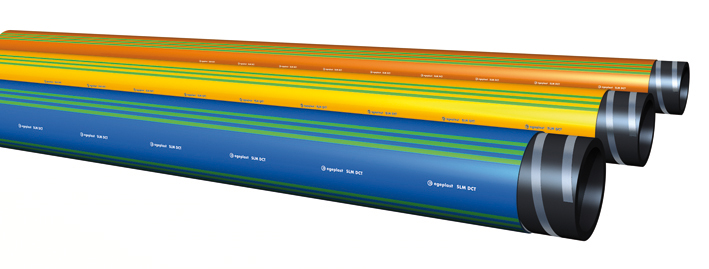

SLM® DCT - Standard pipe made of PE100 RC fitted with a protective PEplus sheath and built-in function test.

For water, sewage and gas. Dim ø 25-1200 mm

SLM® DCT

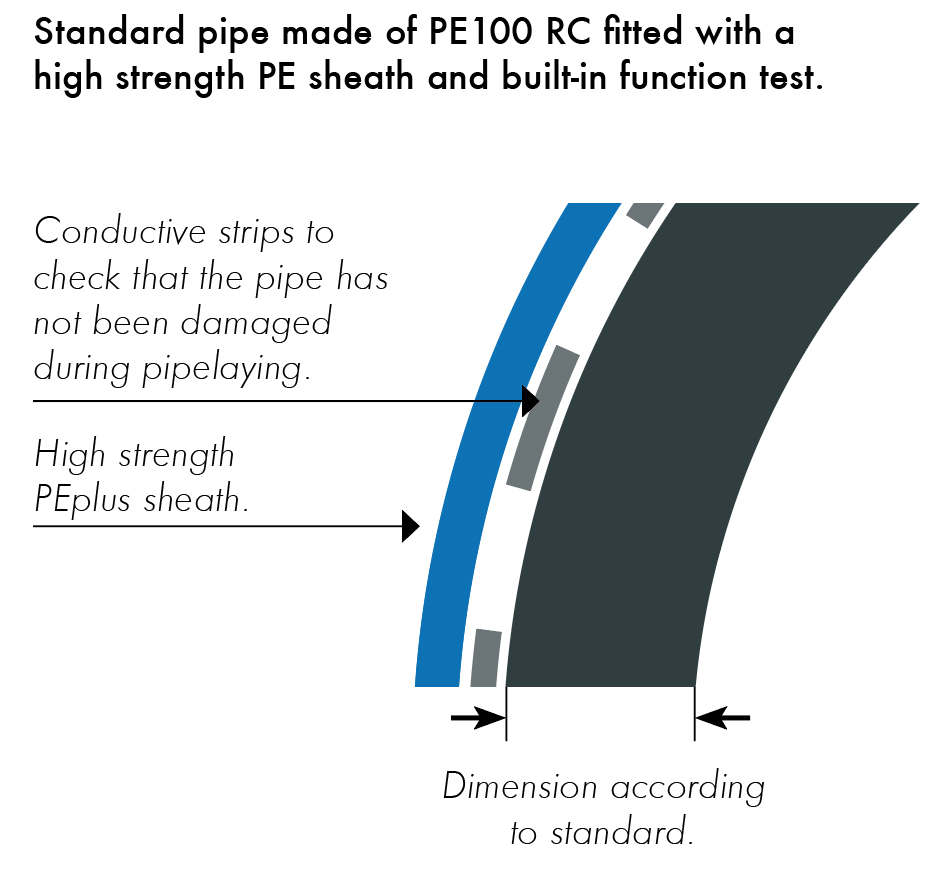

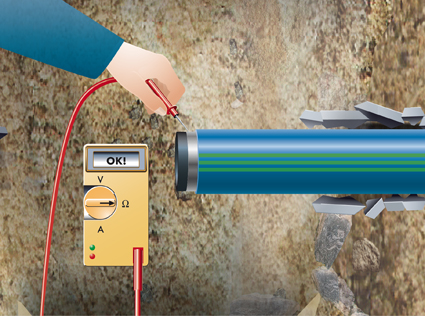

Standard pipe made of PE100 RC fitted with a protective PEplus sheath and built-in function test. SLM® DCT is basically the same pipe as the SLM® 3.0 with a high strength sheath and made of PE100 RC, but SLM® DCT is also fitted with conductive aluminium strips between the pipe itself and the protective sheath. A pipe can usually be checked via internal filming, but the integrated conductive strips also allow you to check that the pipe has not suffered any external damage in connection with installation. The design also allows permanent monitoring and detection of the installed pipe system. SLM® DCT is designed to be used primarily in alternative installation methods such as directional drilling or pipe splitting. The pipe must be stripped both when butt welding and when using an arc welding sleeve.

Extra protection against scratches and point loads

The high strength pipe sheath is made of PEplus and has a thickness equivalent to e.g. 25% of the pipe’s wall thickness in dimension 250 mm/SDR17. In addition to protecting against scratches and slow crack growth, the high strength sheath also helps to distribute the pressure from any point loads over a larger surface, thereby reducing impact on the main pipe.

Standard pipe made of PE100 RC fitted with a protective PEplus sheath and built-in function test. SLM® DCT is basically the same pipe as the SLM® 3.0 with a high strength sheath and made of PE100 RC, but SLM® DCT is also fitted with conductive aluminium strips between the pipe itself and the protective sheath. A pipe can usually be checked via internal filming, but the integrated conductive strips also allow you to check that the pipe has not suffered any external damage in connection with installation. The design also allows permanent monitoring and detection of the installed pipe system. SLM® DCT is designed to be used primarily in alternative installation methods such as directional drilling or pipe splitting. The pipe must be stripped both when butt welding and when using an arc welding sleeve.

Extra protection against scratches and point loads

The high strength pipe sheath is made of PEplus and has a thickness equivalent to e.g. 25% of the pipe’s wall thickness in dimension 250 mm/SDR17. In addition to protecting against scratches and slow crack growth, the high strength sheath also helps to distribute the pressure from any point loads over a larger surface, thereby reducing impact on the main pipe.

Product benefits

- Pipe system made of PE100 RC for a safer service life and more efficient pipelaying.

- Built-in function check via conductive aluminium strips between the pipe itself and the outer sheath allows external pipe damage caused during pipelaying to be detected and localized.

- High strength PEplus sheath corresponding to e.g. 25% of the pipe’s wall thickness at dimension 250 mm/SDR17.

- A pipe system suitable for alternative installation methods where extra pipe protection is required.

- Minimal ovality for safe jointing.

- Complete range of pipe fittings.

Pipelaying method

Traditional pipelaying in trenches.

Suitable for pipelaying adapted for pipes made of PE100 RC.

Also suitable for alternative installation methods.

Built-in function test.

Approvals

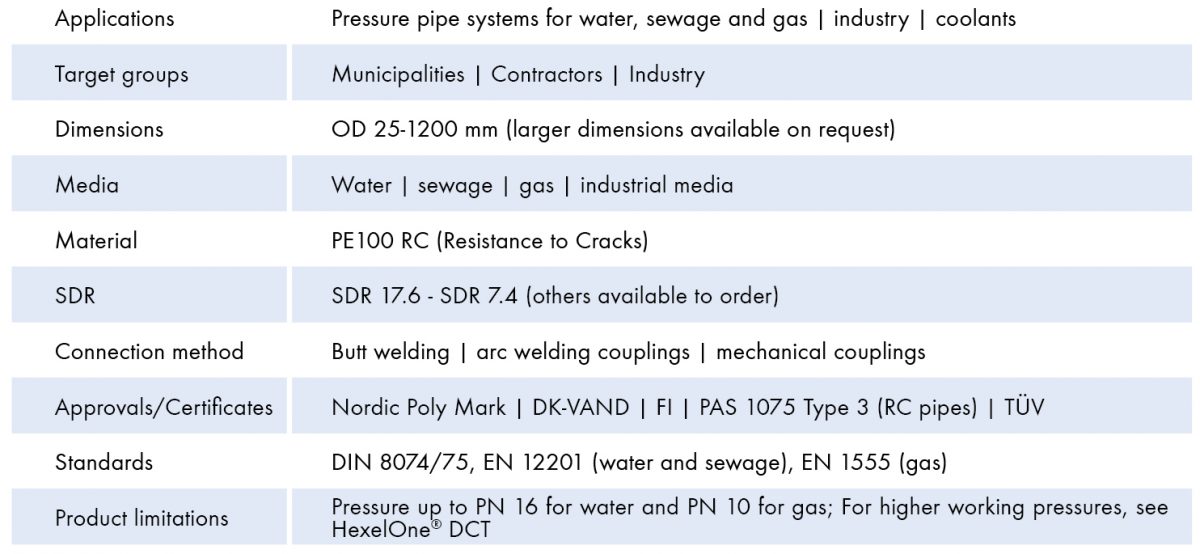

Facts

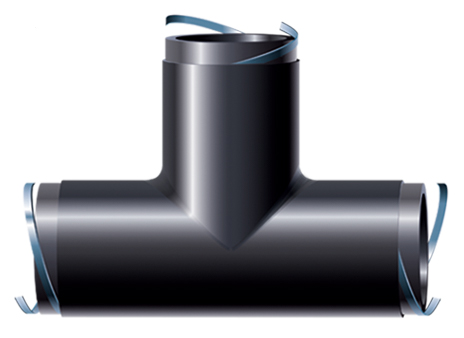

Pipe fittings

PE pipe fittings

– Injection moulded

– Seamless

– Machined

– Segment welded

Arc welding parts

Complete range of arc welding parts for different purposes.

Flange joints

Wide range of flange joints such as loose flanges, SF flanges and HP flanges.

Custom pipe fittings

A range of customized pipe fittings is available for SLM® DCT. Also custom manufacture according to drawing.

Delivery options

Coil

Drum

Straight lengths

6, 12, 18, or 20 m

- All pipes are fitted with end caps

- Non-standard lengths can be ordered on request