Home » High strength sheath

Pipes with an extra thick sheath in PEplus

Homogeneous pipes and multilayer pipes – what’s the difference?

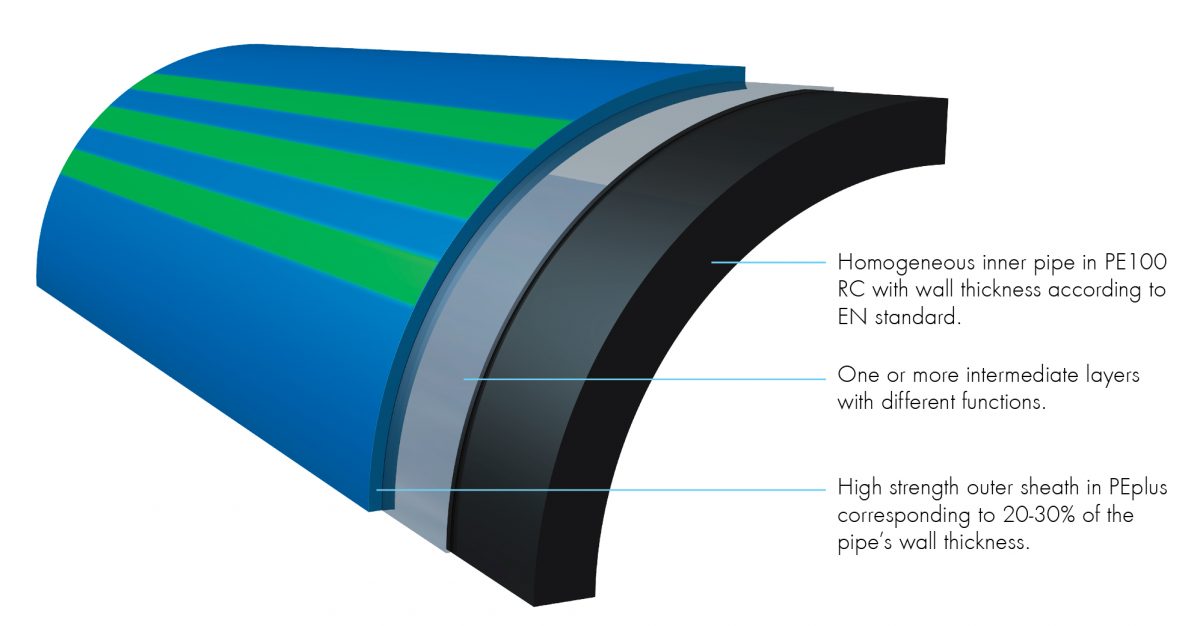

There is confusion in the market around homogeneous pipes and multilayer pipes and the difference between them. In simple terms, a homogeneous pipe consists of a single layer inside and out, while a multilayer pipe consists of a main pipe and an outer sheath. Between this outer sheath and the main pipe, additional layers can also be added to provide the pipe with various functions, such as a vapour barrier, online damage control monitoring and the ability to withstand extra high pressures, or a combination of these.

The confusion usually occurs when homogeneous pipes are supplied with colouration on the outermost part of the pipe. This colouration, however, which is intended to facilitate the location of any scratches and cracks that may occur during pipelaying, is not a layer in itself, but a part of the main pipe. Another big difference between these pipe types is how they are handled during jointing. For example, homogeneous pipes must never be stripped during arc welding (a homogeneous pipe simply does not have an outer layer that can be stripped).

PE sheath corresponding to e.g. 25% of the thickness at dimension 250 mm

Sheathed pressure pipes, also known as “coated pipes”, are equipped with an outer sheath that may be made of various materials, the most common of which are polypropylene (PP) and polyethylene (PE). Extena’s sheathed pipes have a PE-plus sheath made of high density polyethylene. The thickness of the sheath increases with the dimension of the pipe, from 2 to 5 mm. In dimensions up to 355 mm/SDR17, the sheath thickness corresponds to approximately 20-30% of the pipe’s wall thickness. In dimensions over 355 mm, the thickness is a slightly lower percentage, but the thickness of the sheath in mm is in fact larger. Pipes with high strength Extena sheaths must not be confused with the thin layers of less than 1 mm that some pipes on the market are fitted with. Since both pipe and sheath are made of polyethylene, the sheath does not need to be removed during butt welding (SLM® 3.0) but can be integrated into the joint, reducing the risk of the sheath being ripped off when performing alternative installation methods such as directional drilling, pipe bursting and pipe splitting. Recovery (regranulation) is also simplified as the sheath does not need to be separated from the main pipe. However, when using an arc welding sleeve, the outer sheath must always be removed.

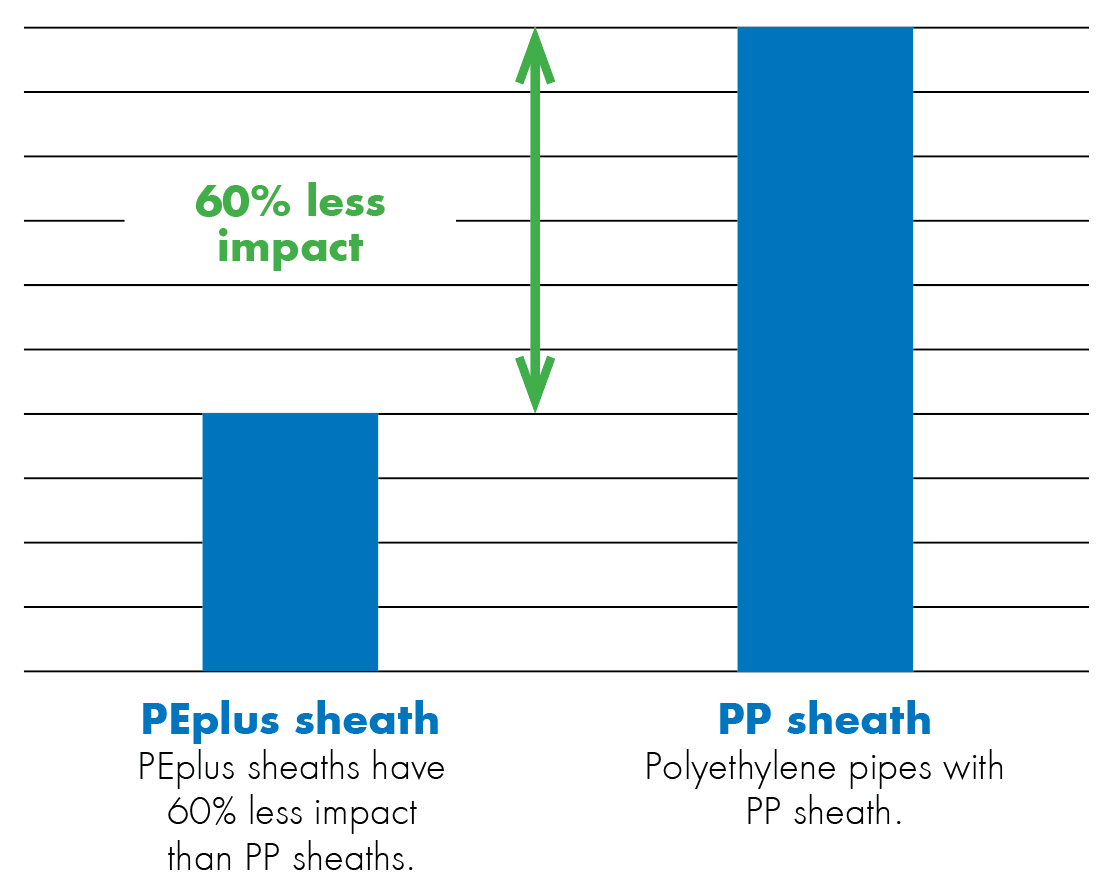

PE sheath offers 60% less wear than PP

PEplus is a patented HD-PE with a higher molecular weight that makes the coating more scratch resistant compared to conventional grades. We have chosen this durable, scratch resistant material because the sheath is only a protective layer that is not included in the dimension of the pipe. Tough tests have shown that our PEplus sheath offers 60% less wear on the outer layer of the pipe compared to a polypropylene sheath.

Abrasion tests according to DIN EN ISO 15527 show that a sheath made of patented PEplus with a higher molecular weight has 60% less impact than a sheath made of polypropylene PP.